Napoleon Engineering Services Announces Rolling-Contact Fatigue and Wear Testing

Five-Ball Tester

The NES Five-Ball tester captures many of the intricate mechanics of bearing fatigue making it very attractive for simulation of full scale bearing testing of ball bearings without full scale costs.

The upper drive ball simulates the inner ring, the cup supporting the lower four balls models the outer ring and the four planetary balls replicate the balls in a bearing. Five-Ball testing can be used to qualify ball manufacturers, verify material lot integrity, investigate lubricant effects on fatigue life, study ceramic ball material and process quality, and determine heat treatment life factors. This modern version of the original NASA testers is designed to run at speeds up to 10,000 rpm and stress levels up to 900 ksi (6.2 GPa) on ball diameters up to 1¼”. The NES tester controls lubricant flow, oil temperature, rotational speed and applied load while monitoring support cup temperature and system vibration for automatic shutdown.

Cylindrical Roller Tester

Testing of individual cylindrical rollers outside of a full scale bearing can now be achieved using the NES Cylindrical Roller Tester (CRT). Testing ceramic roller quality or evaluating the influence of crown geometry on roller life can now be done cost effectively and without the risk of inner or outer ring failure. The NES CRT can accommodate 7mm x 7mm rollers up to 14mm x 14mm making it an ideal test bed for aerospace roller geometry and material research and development. Testing of ceramic roller to validate material and process integrity at high stress levels can be achieved on the CRT. Stress levels as high as 450 ksi (3.1 GPa) can be achieved with multiple stress cycles per roller rotation resulting in short test times without the need for complete bearing testing and resulting ring failures. The CRT allows for validation of material, surface, form, and process integrity for end users, roller manufacturers and bearing manufacturers alike.

Five-Ball Tester

The NES Five-Ball tester captures many of the intricate mechanics of bearing fatigue making it very attractive for simulation of full scale bearing testing of ball bearings without full scale costs.

The upper drive ball simulates the inner ring, the cup supporting the lower four balls models the outer ring and the four planetary balls replicate the balls in a bearing. Five-Ball testing can be used to qualify ball manufacturers, verify material lot integrity, investigate lubricant effects on fatigue life, study ceramic ball material and process quality, and determine heat treatment life factors. This modern version of the original NASA testers is designed to run at speeds up to 10,000 rpm and stress levels up to 900 ksi (6.2 GPa) on ball diameters up to 1¼”. The NES tester controls lubricant flow, oil temperature, rotational speed and applied load while monitoring support cup temperature and system vibration for automatic shutdown.

Cylindrical Roller Tester

Testing of individual cylindrical rollers outside of a full scale bearing can now be achieved using the NES Cylindrical Roller Tester (CRT). Testing ceramic roller quality or evaluating the influence of crown geometry on roller life can now be done cost effectively and without the risk of inner or outer ring failure. The NES CRT can accommodate 7mm x 7mm rollers up to 14mm x 14mm making it an ideal test bed for aerospace roller geometry and material research and development. Testing of ceramic roller to validate material and process integrity at high stress levels can be achieved on the CRT. Stress levels as high as 450 ksi (3.1 GPa) can be achieved with multiple stress cycles per roller rotation resulting in short test times without the need for complete bearing testing and resulting ring failures. The CRT allows for validation of material, surface, form, and process integrity for end users, roller manufacturers and bearing manufacturers alike.

NES Fretting Wear Tester

The NES fretting wear tester is based on ASTM D4170 standard test method for fretting wear protection of lubricating greases; however, it is also designed to allow for increased oscillation angles and can be used to validate proof of concept wear solutions under aggressive fretting and oscillating conditions.

The NES fretting wear tester is an ideal platform to evaluate the influence that material, dry film lubricant, coatings, plating, cage material, grease, or manufacturing processes have on wear. The machine tests two thrust ball bearings with an axial load applied at oscillation angles up to ± 30°. This tester provides test results within days with low cost sample preparation.

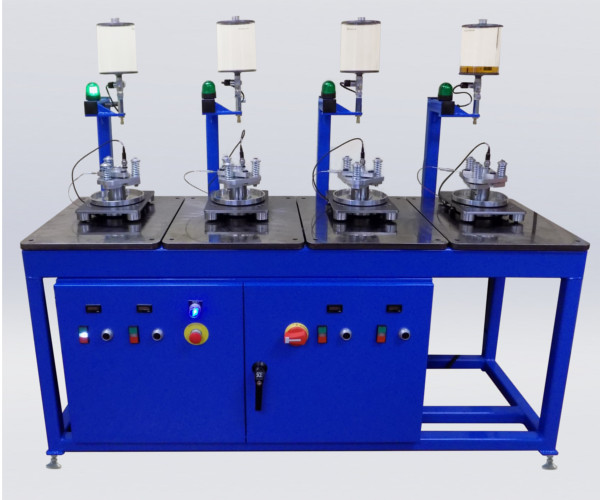

NES Fretting Wear Tester

The NES fretting wear tester is based on ASTM D4170 standard test method for fretting wear protection of lubricating greases; however, it is also designed to allow for increased oscillation angles and can be used to validate proof of concept wear solutions under aggressive fretting and oscillating conditions.

The NES fretting wear tester is an ideal platform to evaluate the influence that material, dry film lubricant, coatings, plating, cage material, grease, or manufacturing processes have on wear. The machine tests two thrust ball bearings with an axial load applied at oscillation angles up to ± 30°. This tester provides test results within days with low cost sample preparation.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Zero-Max Load Adaptors Connect Pump Impellers in Underwater Applications

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.