Development of “Low Friction Hub Bearing II” Reducing Rotational Friction by 50% - NTN

Resource from: CBCC Likes:244

Nov 02,2017

Reduce rotational friction while driving by 50% and improve vehicle fuel efficiency by approximately 0.42%

NTN Corporation (hereafter, NTN) has developed the “Low Friction Hub Bearing II” which reduces rotational friction by 50%, and contributes to the control of greenhouse gas emissions that are becoming severe every year.

Since environmental regulations are continuing to be introduced and regulated more strictly in Japan, the Americas, Europe and emerging countries, demands of fuel efficient vehicles such as hybrid vehicles and electric vehicles (EV) keep growing accordingly. In addition emphasis is being placed on reducing energy while vehicle is driving, and there is a demand to further reduction for rotational friction in order to get better efficiency for fuel and electric consumption even for hub bearings that support axle.

NTN has developed a hub bearing that greatly reduces rotational friction compared to conventional products by adopting low viscosity grease for seal, improving the sliding surface of seal and low friction grease for bearing, and has been developing a market for the product.

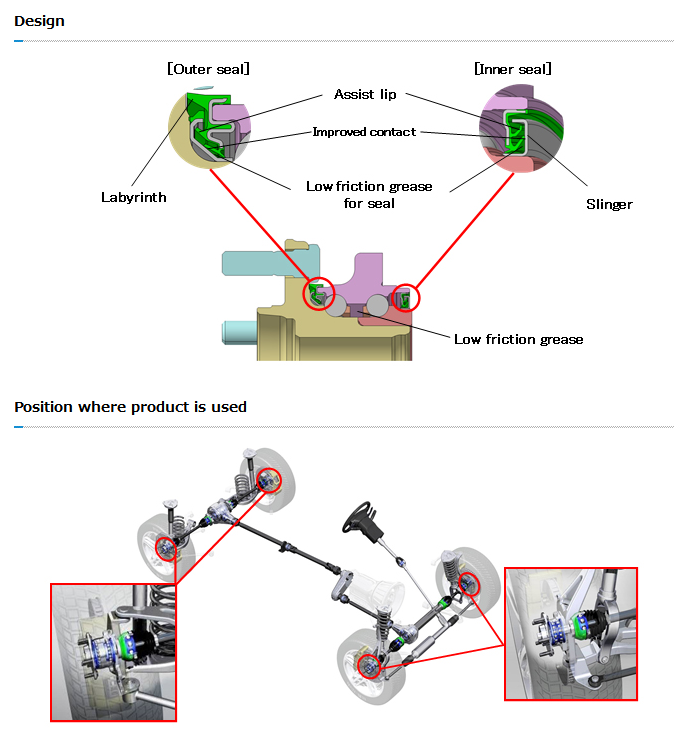

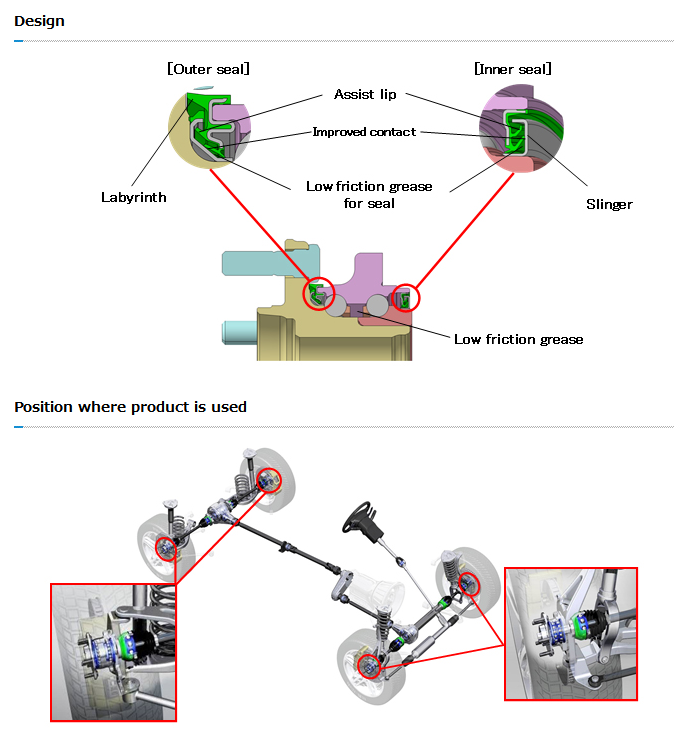

By redesigning the seal structure and optimizing the shape, NTN has developed the “Low Friction Hub Bearing II” which reduces rotational friction by 50% compared to conventional products without affecting muddy water resistance and improves fuel efficiency of vehicle by approximately 0.42%. It is general to apply three contacted seal lips in order to ensure muddy water resistance, however this developed product has a reduced number of lips that make further low friction. NTN could maintain a high muddy water resistance with creating a labyrinth structure (clearance) in the seal and optimizing seal shape in order to cover expected some reduction of muddy water resistance due to reducing the number of contacted seal lips. The composition and viscosity of grease were also revised, and the grease that contributes to torque reduction is adopted.

The “Low Friction Hub Bearing II” is shown at the “Tokyo Motor Show 2017” held from October 27 to November 5 at Tokyo Big Sight.

Features

Reduce hub bearing rotational friction by 50% (compared to conventional products)

(1) Developed and adopted a new type seal structure with labyrinth

(2) Adopted low friction grease (revised composition and viscosity)

Inquiries about this release

Product photo

()

【CBCC News Statement】

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.