NTN to Begin Mass-production of Newly Developed Axial Type “Multi Track Magnetic Ring”

Thin and lightweight for high-accuracy detection of robot joint angles

NTN Corporation (hereafter, NTN) has added a newly developed “axial type” of “Multi Track Magnetic Ring”*1 to the “radial type.” The developed product makes up thin, lightweight and high-accuracy angle detection sensor systems and its mass-production from July 2018.

With the remarkable advances made to robotic systems in recent years, position control with a higher level of accuracy will be required. The various components used for robots are becoming more compact and lightweight, and robot joints in particular need to have a hollow shape with thin walls to allow wiring cables to pass through internally, for which small angle sensors with hollow shafts (φ25 mm or less) are generally used. The high-resolution, high-accuracy optical sensors often used in multijoint robots also have issues where they cannot function in environments with dust or oil present.

To address these issues, NTN has applied the magnetic ring and magnetization technology developed for products such as the Integrated Sensor Bearings and Hub Bearings with ABS Sensor to develop the “Multi Track Magnetic Ring” that features a magnetic sensor with the same high-resolution and high-accuracy as optical sensors.

The “Multi Track Magnetic Ring” is a ring-type product developed mainly to detect the angles of robot joints which, when combined with the dedicated magnetic sensor IC*2, outputs data of absolute angles to at 17 to 20 bit (resolution of approx. 0.0027° to 0.00034°) that is adequate for angle detection. Being a magnetic type, it has superior resistance against vibrations, high temperatures, dust, oil mist and similar environments compared to optical types. The newly developed axial type “Multi Track Magnetic Ring” is thin with an axial width dimension of 4 mm, which can contribute to more compact devices. It has a hollow shape that is large enough to pass through cables internally (internal diameter φ41 mm), which means it is easy to apply for robot joints.

NTN is strengthening its robot-related businesses as a type of new business field in the Medium-term Management Plan “DRIVE NTN100” that began in April this year. NTN will begin mass-production of the developed product for robot manufacturers, and continue identifying market requirements to increase size variations as a way of expanding business.

-

Press release: Development of “Thin Type High Precision Angle Sensor”

(New name: Multi Track Magnetic Ring)

https://www.ntnglobal.com/en/news/new_products/news201700034.html -

Magnetic sensor IC combined with Multi Track Magnetic Ring:

iC-Haus GmbH (Germany) iC-MU

https://www.ichaus.de/product/iC-MU

Developed product features

| 1. | High resolution: 17 to 20 bit (resolution approx. 0.0027° to 0.00034°) |

|---|---|

| 2. | Thin, lightweight and hollow shape |

| 3. | Performance: magnetic type for superior environment resistance against vibrations, high temperature, dust, oil mist, etc. |

| 4. | Allows absolute angle detection |

Applications

- Encoders for angle detection of robot joints

- Encoders for motor rotation angle detection

Inquiries about this release

Product photo

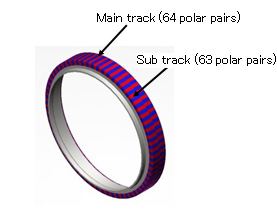

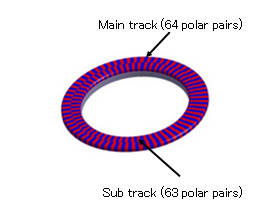

| Radial Type | Axial Type |

|

|

Specifications

| Radial Type | Axial Type |

|---|---|

Outer diameter:φ51.5mm

Internal diameter:φ44mm

Axial width:8.2mm

Mass:10.7g

|

Outer diameter:φ56mm

Internal diameter:φ41mm

Axial width:4mm

Mass:9.8g

|

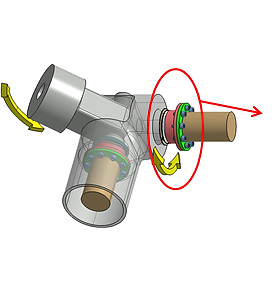

Examples of application

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next JW Winco Offers Clamping Levers with Eccentrical Cam

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.