Timken Tips for Lifting Large Bearings

Special tools and bearing modifications can make removal and installation much safer and easier for plant technicians.

Large bearings deserve extra consideration when removing and reinstalling components in heavy machinery. Particularly in rolling mills and manufacturing plants where a single bearing can weigh thousands of pounds, it is paramount to follow industry standards for lifting bearings properly and safely. The Timken Company repairs thousands of bearings a year for customers worldwide and often observes damage that is attributable to lifting and handling mistakes that could have been avoided.

The service life of any bearing depends greatly on the care and maintenance it receives. This is especially true in industrial applications, where operating conditions tend to be harsh, loads are heavy, and contamination from dirt and scale are common. Following correct lifting practices is a critical step to ensuring long-running bearings that minimize the cost of ownership.

Even the most experienced plant technicians and maintenance professionals are encouraged to review the following recommendations for lifting large bearings. Lifting standards have changed in recent years, and legacy lifting devices may not be as effective as some might think. Brushing up on the basics only takes minutes and costs nothing compared to the expense of repairing a damaged bearing.

Different Methods for Different Bearings

There are many types of bearings, and each has its own removal process. Smaller bearings can typically be extracted by hand or with the help of a mechanical puller device that can be obtained from the bearing manufacturer or approved vendor. For bearings installed with a press fit or that cannot be removed with a puller for other reasons, often the inner ring of the bearing can be heated to ease removal. This is usually accomplished using a heat lamp or similar device. (NEVER use a torch to heat the inner ring as it can alter the properties of the bearing steel.)

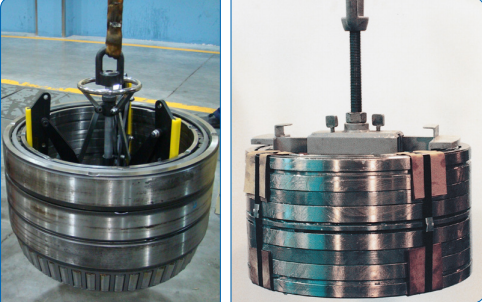

Handling larger bearings requires a crane and some simple fixtures—typically a variety of slings, hooks, chains and mechanical devices—to safely conduct maintenance. Some large bearings are manufactured with tapped holes in the face of the inner or outer rings to allow eyebolts or hoist rings to be inserted (Figure 1). Other bearings have threaded lifting holes in the cage ring that can be used to lift the inner ring assembly.

Thus, it is risky to assume that any one removal method or device will work for all bearings. Always be sure of the manufacturer’s exact requirements for lifting large bearings, and exercise added caution when handling bearings that are equipped with a cage, as the cage tends to be the component of the bearing that is most deformable and susceptible to damage.

Lifting Large Bearings

Two ASME standards—BTH-1-2017 and B30.20-2018—govern the lifting industry with concern to below-the-hook devices. In simple terms, ASME states that a below-the-hook lifting device is “a device used for attaching a load to a hoist. The device may contain components such as slings, hooks, and rigging hardware… ” Bearing lifters fall into this category.

Most heavy industrial facilities own some type of lifting equipment, having used the same rig for decades or, in other cases, a fabricated solution that takes advantage of the available tooling at the plant. While these lifting fixtures may function effectively, many such legacy or custom-built devices may not adhere to today’s lifting standards.

Investing in a purpose-built lifting assembly is a wise choice when it comes to large bearing maintenance, especially in plants where several bearing lifts a week are required. Two lifting devices are common across all industries—three-legged fixtures and sliding-foot fixtures (Figure 2). These fixtures can be used to remove bearings from the housing and reinstall them after completing maintenance.

Three-legged fixtures are used to lift the entire bearing or to handle one subassembly at a time while maintaining concentricity of the bearing components. Keep in mind that certain fixtures may work for certain types of bearings but not others. For instance, in an application where a bearing changes from an open to a sealed design, there is the potential for bearing seal damage to occur due to the length of the legs of the old fixture.

A sliding-foot fixture, meanwhile, engages the bottom row of the bearing assembly, allowing removal of the entire assembly at once, which can then be stacked outside the housing, thus reducing the risk for raceway damage to occur. This method does require ample overhead crane capacity and the availability of machined reliefs in the chock that will allow for the feet of the lifting fixture to properly engage the bottom row of the bearing assembly. Hence, the use of a sliding-foot fixture can be limited in some instances.

Bearing Features for Easy Lifting

As noted above, bearing features can make lifting individual components much easier and safer when removal of the entire assembly is not required. These features typically include tapped holes in the face of the bearing race for eyebolt and chain lifting, blind holes in the bore of the inner ring allowing the use of turnbuckle-style lifting devices.

It is advisable to consult bearing makers directly about the features that will provide the optimal lifting arrangement for a given application. Depending on the bearing design, adding lifting features may in fact compromise a bearing’s integrity. At the same time, proper lifting practices are essential for safe handling.

Consider what can happen when correct procedures are not followed, where a large four-row cylindrical roller bearing having eight tapped lifting holes in the cage (set up as four pairs to accommodate a crossbar through the eyebolts) is lifted using only two eyebolts, causing fracturing of the welds that join the roller pins to the cage. This can require the assembly to be repaired before the bearing can be used again, or where damage is severe, the assembly may even come apart, causing components to fall to the ground.

Also, be sure to lift bearings only from a level, stationary position to avoid potential problems. During installation, for example, large bearings are sometimes propped at an angle or may be resting against a table in preparation for handling. Hence, the eyebolts may not bear the load of the lifting chain evenly, which can result in broken eyebolts and stripped lifting holes, creating a serious safety hazard.

A Little Care Goes a Long Way

It is critical to follow proper lifting practices for large bearings to attain reliable operation with the lowest possible ownership cost. Tools for lifting bearing components and assemblies should be evaluated during the early stages of a facility upgrade or maintenance cycle, and plant technicians should engage bearing makers in conversation about product modifications that can make their lives easier. With simple planning, additional safe handling features can be implemented before bearings are shipped and installed, saving potentially tens of thousands of dollars for every accident or incident avoided.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ICL Boulby sets new weekly polyhalite mining record

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.