NSK Develops Lift-Rotation Z-θ Actuator Unit

Compact design fits inside vertical machine tools and injection molding machinery. Increase productivity per square meter of floor space.

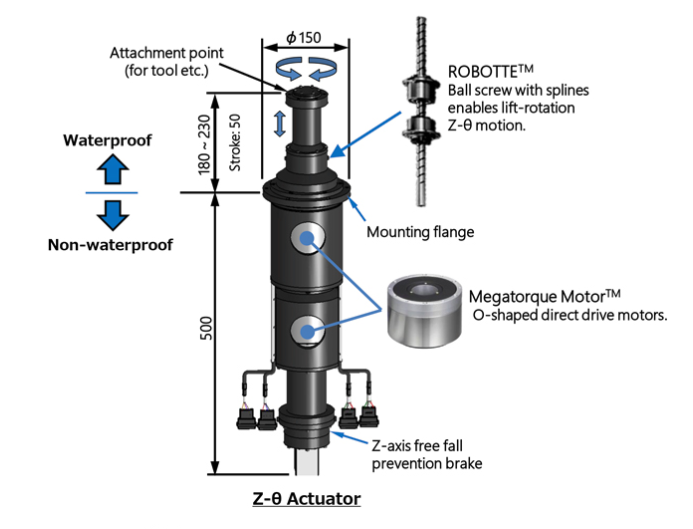

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President & CEO: Toshihiro Uchiyama) has developed a new actuator unit that delivers lift-rotation Z-θ motion (coaxial rotation and linear motion) in a compact rod-shaped package.

The versatile unit uniquely integrates motor, ball screw with spline, and brake mechanism to achieve high performance Z-θ motion with a small footprint. A waterproof upper structure enables the unit to handle challenging splash-and-spray (wet) manufacturing environments.

NSK will be exhibiting a working prototype at International Robot Exhibition 2019 (iREX 2019), to be held at Tokyo Big Site from December 18-21, 2019.

The Z-θ actuator offers a new value proposal of increasing productivity per square meter of floor space. NSK is preparing to launch the product in the near future, and units are available for trial implementation and verification testing by customers.

Development Background

There is a recent trend toward downscaling manufacturing procedures, a process which is measured by calculating productivity on a plant floor space (per-square-meter) basis. Downscaling of machinery is taking shape through compact vertical machining centers and vertical injection molding machines, with many such machines recently hitting the market.

General manufacturing automation employs robots to transfer and convey workpieces (product) between manufacturing processes. SCARA robots are often used for pick-and-place transfer tasks, but are limited by nature of their design in that they cannot place items near their own arm support base. This results in SCARA robots taking up significantly more floor space than necessary, thereby reducing productivity on a plant floor space (per-square-meter) basis.

The newly developed lift-rotation Z-θ actuator unit delivers coaxial rotation, linear motion, motor, and brake mechanism in a small rod-shaped package with a waterproof upper structure. The compact design of the Z-θ actuator makes it easy to integrate directly inside vertical machining centers and injection molding machines.

Features

Combination of direct drive motor and linear motion technology achieves lift-rotation Z-θ motion (coaxial rotation and linear motion) in a compact rod-shaped package.

High-speed high-accuracy positioning through combination of NSK Megatorque Motor™ and ROBOTTE™ technology (gearless/beltless structure).

O-shaped (hollow) Megatorque Motor enables highly compact rod-shaped unit design.

Integrated brake mechanism prevents shaft from dropping under its own weight.

Integrated absolute position sensor.

The upper section of the unit is waterproof, making it ideal for use in splash-and-spray (wet) manufacturing environments.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ICL Boulby sets new weekly polyhalite mining record

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.