Siemens Network Technology Ensures Efficient Operation at Container Port Terminal

Over 70 percent of all break-bulk cargo (piece goods) in the world is transported by ship, train, or truck in ISO containers (standardized large-volume containers). Cutting-edge container terminals are therefore essential to ensure goods are handled efficiently. A well-known provider of these solutions is relying on a high degree of automation and Siemens communication and network technology when building a new container port terminal. A total of 42 cranes are controlled and automated using the largely redundant, reliable network. The pre-configured and tested devices were commissioned in successive stages. By ensuring the automation and PC systems were completely separated, the network retains a high level of availability, thus making a significant contribution to the efficiency of the container terminal.

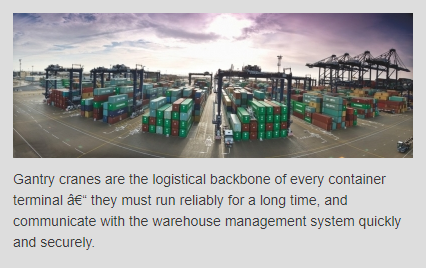

Gantry cranes are the logistical backbone of every container terminal – they must run reliably for a long time, and communicate with the warehouse management system quickly and securely. The reliability of a crane network is largely dependent on being able to transmit transport orders quickly, smoothly, and tamper-proof to the respective crane. When building a new container port terminal, the client therefore relies on Siemens crane, automation, and network technology. The final expansion stage of the plant will have 42 fully automated stacking cranes interacting across three storage segments, each with seven storage blocks. Two cranes service each storage block. Manned straddle carriers which transport the containers connect the cranes and the storage blocks. Siemens RFID (Radio Frequency IDentification) technology is used to track the containers.

Core components of the network solution implemented with Siemens Professional Services are over 300 Scalance switches series X-500, X-300 and X-200 for the structured, largely redundant communication among more than 1,000 participants.

Two physically separated networks were used for the automation applications and PC applications so that, for example, data-intensive camera surveillance does not affect other applications. Redundant ring structures and redundancy mechanisms such as the High Speed Redundancy Protocol (HRP) and Standby Coupling, Virtual Router Redundancy Protocol (VRRP) and Open Shortest Path First (OSPF) routing protocol achieve shortest reconfiguration times in the event of a fault – and thus the highest availability of the entire crane network.

The hub of the three-level network solution is formed by Layer 3 Scalance XR552-12M routers – two of each connected to a redundant ring in the operator's data center. One pair is for networking the automation components and the other for PC-based applications. All four routers are connected via a Scalance S615 Industrial Security Appliance to the higher-level backbone of the operator network. The routers communicate with the subordinate, similarly ring-redundant block level – each made up of two series X-300 Scalance Layer 2 switches per block in separate VLAN (Virtual Local Area Network) segments. With four further X-300 and X-200 series switches for each crane, the number of installed Scalance devices increases to more than 300. The network has over 1,000 participants, each of which was allocated a unique IP address so that they can be quickly identified and addressed.

All the devices were intensively tested, pre-configured, and optimized before they were commissioned via Sinema Remote Connect (a management platform for remote networks) using the Scalance Firewall and a secure, on-site VPN (Virtual Private Network) connection. The management platform allows the Siemens experts to engineer the automation systems remotely in the TIA (Totally Integrated Automation) Portal engineering framework and to install firmware updates. Problems which occurred during the step-by-step commissioning were diagnosed and resolved using Sinema Server (software for network monitoring). This convenient handling is prompting the operator to consider using the Siemens solution in addition to existing tools.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ABB Offers Baldor-Reliance EC Titanium Integrated Motor Drive

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.