Tsubaki Conveyor Chain Offers Cost Savings for Commercial Bakery

Producing high quality, consistent baked goods in a batch production requires precise and reliable processes and equipment. For one bakery, the industrial oven it used for producing pre-baked bread rolls required new conveyor chain every two years due to excessive wear. This was an expensive and time-consuming operation that affected the bakery’s production targets. Fortunately, Tsubaki’s expert engineers were able to recommend a specialized chain product that more than doubled service life.

Almost every village in France still has its own boulangerie, a bakery handed down through the generations of a family of master craftsmen. Today, their bakers combine tradition with technology to ensure the very best end products.

In bigger towns, larger scale bakeries also apply high standards as they work to supply supermarkets across their region. They won’t sacrifice quality, so rely on technical solutions with their plant, equipment and processes to achieve the efficiency and cost management they require.

One bakery decided to review its costs and procedures to ensure that its production line was performing to the highest standards. It quickly identified that the tunnel oven used to produce pre-baked bread rolls was requiring a shut-down period for replacement conveyor chain every 1.5 to 2 years. The replacement process required a complete de-mount of the machine, which resulted in expensive maintenance bills. The question that inevitably arose was: “Can we improve the service life of the chain?”

Tsubaki was contacted and its engineers were soon on site to assess the application. The average temperatures experienced by the chain throughout the oven cycle was 240°C (peaking at 300°C), which was causing the inside of the rollers to wear and the chain to fail earlier than expected. Tsubaki identified that a chain designed for operation in hard wearing environments, combined with a specialized lubrication system, could significantly extend the gap between replacement and reduce the Total Cost of Ownership of the oven at the same time.

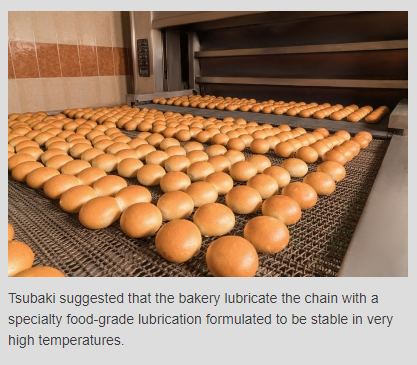

The engineers recommended an engineered solution from its large size conveyor chain catalog that featured heat treated rollers and bushes to ensure smooth interaction, even at high temperatures. The chain has been built for strength and performance to cope with regular loading and delivers stable performance. In this case it was suggested that the bakery lubricate the chain with a specialty food-grade lubrication formulated to be stable in very high temperatures. This is dispensed through an electrically operated gear pump, that is synchronized with the speed of the chain to ensure that an optimized coating is always maintained.

With the new chain installed and the updated lubrication system in operation it wasn’t long until the bakery’s maintenance staff started to notice the difference in performance. Where the chain would usually start to show signs of wear in a few months, the new chain was visibly harder wearing than the incumbent. In fact, the chain proved to offer more than twice the reliability – eventually reaching a service life of over five years. The resulting reduction in periods of non-production has been a significant benefit to the Total Cost of Ownership of the chain, which reflects directly onto the bakery’s bottom line.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next CD-ROM on Voith Fill-Controlled Fluid Couplings

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.