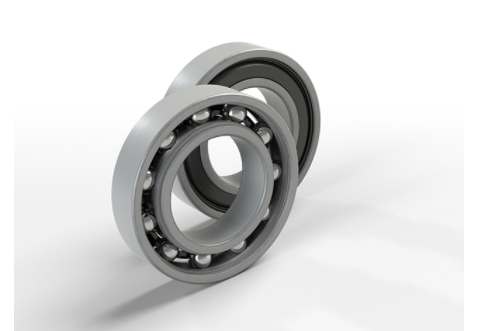

NSK Develops Ultra-High-Speed Ball Bearing for EV Motors

NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President & CEO: Toshihiro Uchiyama) has developed a new ultra-high-speed bearing ideal for electric vehicles, including battery electric, hybrid, and other new energy vehicles.

The new bearing enables electric motors to operate at higher speeds, improving fuel economy (reducing power consumption per unit distance), increasing maximum vehicle range, and contributing to enhanced user comfort. NSK is targeting 10 billion yen in sales by 2030.

1. Development Background

Protecting the environment is vital to the continued prosperity of societies around the world. To enhance sustainability, the automotive industry is rapidly expanding the development and production of electric vehicles, hybrids, and other new energy vehicles. However, maximum range on a single charge remains a concern for consumers, and there is significant demand for larger capacity battery packs and/or improved efficiency to allow for greater flexibility and peace of mind when purchasing battery EV and other new energy vehicles.

In light of these needs, automakers are pursuing smaller and lighter automotive components, and developing faster, higher output motors operating at higher efficiencies. Accordingly, bearings used in powertrains, especially in electric motors, are being subjected to increasingly higher speeds and performance demands.

Bearing rotation during high speed operation can cause grease deterioration due to high temperatures, resulting in bearing seizure/failure. High speeds can also lead to the bearing cage being deformed/destroyed by centrifugal force.

2. Product features

Proprietary NSK Grease Provides Superior Seizure Resistance

The new bearing is filled with a special NSK grease that reduces heat generated during high speed operation, prolonging both grease and bearing life as well as reducing the risk of seizure compared to conventional products.

Newly Developed Cage

Thinner (lighter) retainer tabs reduce cage deformation or breakage due to centrifugal force.

Higher rigidity cage base (spine) resists deformation at high speeds.

The new design significantly reduces deformation of the cage during high speed operation for reliable long-term use.

Newly Developed Cage Material - High Rigidity Cage Resin

High rigidity and high heat resistance reduces cage deformation during high speed operation.

High rigidity reduces effect of centrifugal force, thereby reducing cage deformation during high speed operation.

3. World Leading Performance

Proprietary NSK grease and newly developed cage enable bearing operation at dmN1 = 1.4 million (e.g. 35 mm bore diameter bearing at 30,000 RPM).

1 dmN: A measure of bearing rotational performance. The product of bearing pitch diameter (dm) and rotational speed (N).

4. Customer Benefits

NSK's newly developed bearing offers the highest permissible speeds in the world2 for automotive motors. This enables customers to develop and implement electric motors that operate at significantly higher speeds. Higher motor output contributes to improving fuel economy (reducing power consumption per unit distance), increasing maximum vehicle range, and contributing to enhanced user comfort.

Higher speeds also enable utilization of smaller motors, reducing vehicle weight and increasing space for other components, more battery cells, or a larger vehicle interior.

In pursuit of leading-edge technology, NSK is continuing development and expects to announce bearing models capable of dmN = 1.6 million by the end of 2020.

2 Based on NSK investigation of grease filled automotive bearings.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ICL Boulby sets new weekly polyhalite mining record

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.