Siemens Software Saves Time and Money on Medical Prototypes

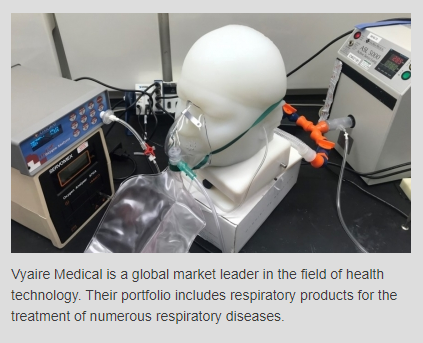

Vyaire Medical (Vyaire) is a global market leader in the field of health technology. Their portfolio includes respiratory products for the treatment of numerous respiratory diseases. To ensure that its products are tailored as accurately as possible to the individual situation of the relevant patient, Vyaire uses precise models based on scans of actual human heads during development. Another essential aspect for the efficient development process is the digital twin of products, which Vyaire creates using software solutions from Siemens Digital Industries Software. This enables the company to largely eliminate physical prototypes, which saves time and money.

Each person takes between 17,000 and 23,000 breaths in a 24-hour period – mostly without any conscious effort. In the event of serious illness, something as simple as breathing can become a struggle between life and death. Vyaire Medical develops special respiratory products for exactly these situations. “Traditionally we were forced to use simplified models in the development of a respiratory mask. We would have used a simplified head model for our CFD (Computational Fluid Dynamics, Ed.) simulations, with idealized breathing holes for the nose and the mouth,” says Dr. Christopher Varga, senior engineering fellow and senior director of research and development at Vyaire Medical. “Today we are using scans of actual human heads – different morphologies of actual patient features.”

Reduced development times can save lives

Patients differ not only physically, but also in their way of breathing. In addition, each patient has a unique breathing profile that depends on their lung function and structure. All of these factors can be taken into account in the simulation of a breathing human. “We are starting to build a library of patient morphologies, which already consists of representative patient geometries for all of the patient populations: adult, paediatric and infant,” explains Varga. Vyaire also makes the most of the opportunities offered by simulation on another level, using Simcenter STAR-CCM+ simulation software from Siemens.

“Having the capability to develop a digital twin of our products using Simcenter allows us to significantly reduce development times by removing the time-consuming process of building and testing physical prototypes,” says Varga. He believes that the biggest benefit realised by the Siemens solution is time. “We can make products much quicker and that of course is very important in today’s environment.”

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next ICL Boulby sets new weekly polyhalite mining record

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.