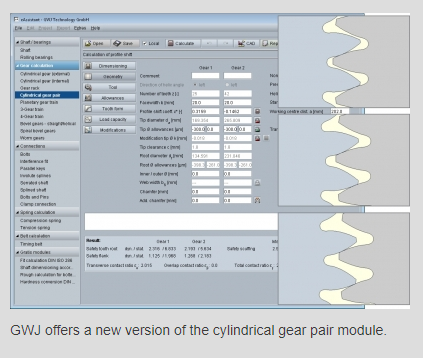

GWJ Technology Offers Enhanced Calculation of Cylindrical Gears

GWJ Technology GmbH from Germany has updated the calculation module for cylindrical gears in its web-based software solution eAssistant.

In addition to various dimensioning functionalities for the distribution of the profile shift, a new function for disconnecting the center distance from the profile shift was added. By using the function "Fixed working center distance (recalculation)," the profile shift coefficients can be defined independently from the center distance. This enables, for example, the calculation of existing gear pairs that are to be installed in the housing with the "wrong" center distance. Transverse contact ratio, backlash and load capacity are also calculated correctly in this case. This function can also be used for the calculation of small-module gears.

The functionality of tools with shifted profile reference line has been extended. Additionally to the addendum coefficient haMP0* of the shifted profile, the dedendum coefficient hfMP0* is displayed and visible in the calculation report. The dedendum coefficient hfMP0* can also be defined by clicking the "Lock" button so that the dedendum coefficient hfP0* of the converted, non-shifted basic rack profile is always 1.0 according to DIN 867.

The option "Full radius" for the tip form of gear shaper cutters has now also been added to hobs. For the definition of load spectra, the user can specify the face coefficient KHbeta and the temperature for each load case. This enables the automatic transfer of values directly from the system extension "SystemManager" to the "Cylindrical gear pair" module in the background. The user can see directly the effects of flank modifications on the root and flank safeties of the gear in the system.

In addition to the common calculation methods for the load capacity DIN 3990, ISO 6336 and ANSI/AGMA 2101, the calculation method VDI 2736 for plastic gears was added to the cylindrical gear module.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Thailand gears up for motor show as pandemic restrictions ease

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.