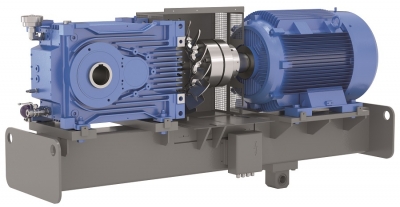

NORD Offers MAXXDRIVE XT Gear Units for Conveyor Applications

Two-stage MAXXDRIVE XT right-angle gear units from NORD are ideal for belt conveyor systems in heavy-duty applications such as the bulk material and mining industries. Available in seven case sizes, these rugged units provide powers from 50 – 1500 hp, output torques between 130,000 – 600,000 lb-in., and speed ratios from 6:03 – 22.4:1. They can also cover ratios up to 30,000:1 when paired with an auxiliary primary stage gear unit.

MAXXDRIVE XT right-angle industrial gear units from NORD have a high thermal load capacity without the need for external cooling thanks to their strong ribbed design, enhanced axial fan design, and air guide covers. They are designed to keep conveyors running even under the harshest conditions, ensuring materials flow smoothly through the entire system. Additionally, large roller bearings and center distances increase the load capacity and service life of components, reducing the amount of routine maintenance required to keep the units operational, while a shaft axis offset allows for an incredibly compact design.

The MAXXDRIVE series is known for its vast configuration options, and MAXXDRIVE XT units are no different.These units can be individually configured for even the most specialized functions, including those where low speed ratios and high power are both required. Gear units used for these types of applications need to be extremely robust and highly resistant to dirt and debris while operating. With that in mind, all MAXXDRIVE bearing and sealing surfaces are machined in a single process, greatly reducing the possibility of contaminants entering the drive cavity and allowing for extremely quiet operation compared to other industrial gear units. Whether used in belt conveyor systems, mixers, mills, sorting drums, or crushers, MAXXDRIVE industrial gear units can achieve very high output torques, making them a go-to solution in heavy-duty applications for more than ten years.

NORD products are based on a comprehensive modular system, allowing customers to easily configure drive systems from a wide selection standard variable frequency drives, motors, gear units, coupling systems, and braking systems – each with their own unique set of options and features. NORD produces geared motors for both horizontal and vertical conveyor systems, all of which have a one-piece housing design that tolerates extremely high transverse forces and torque loads. This also applies to the very powerful MAXXDRIVE industrial gear units, which are required where conveyor inclines are very steep or where high material quantities need to be transported.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next SKF and University of Twente Open State-of-the-Art Technology Center

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.