Siemens Offers Faster E-Motor Production with Wire Brake Application

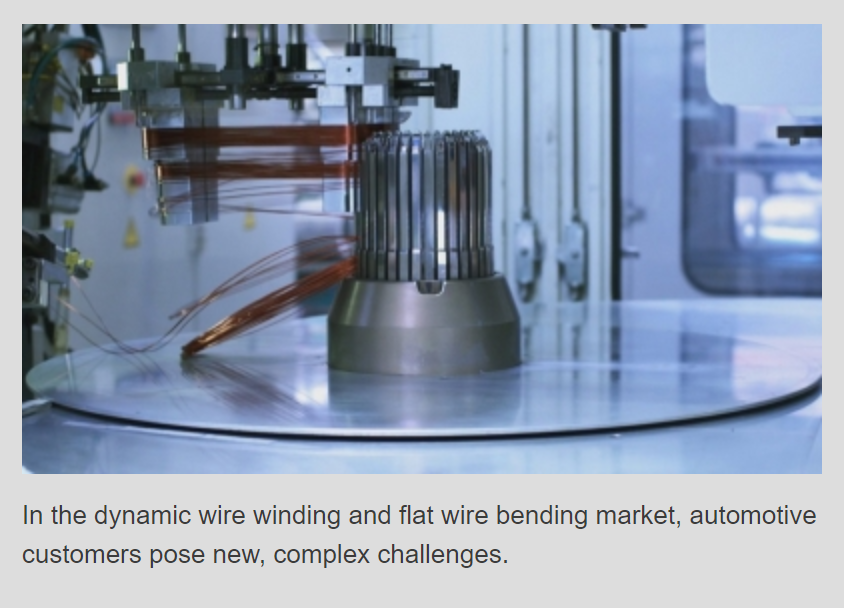

For the faster production of e-motors, Siemens has developed a new application which optimally controls wire tension for linear winding and minimizes fluctuations in force. The Wire Brake software application for automated winding of rectangular coil former controls the tension of the copper wire. In comparison to passive systems, this enables higher winding speeds and a higher winding quality to be achieved. The functionality can be integrated directly into the machine project using the standard library "Simotion Wire Brake" which shortens engineering and commissioning costs. It contains algorithms which include the rectangular geometry of the coil former as well as the "TensionControl" components to control the wire tension brake axis and "CamGeneration" to calculate cams using reference values.

Continued growth in electrification, digitalization and electromobility is leading to increased demands on machines for the automated production of electrostators for electric motors. In addition to maximum productivity, shorter setup times for changing products, and high winding quality, this trend is also focused on plant availability and use in the powertrain. Siemens offers a comprehensive portfolio for the integrated automation of the entire manufacturing process for electric motor manufacturing and the recording of the required process parameters. The Simatic S7-1500 controller and the Simotion motion control system are ideal from simple applications to tasks in the high-end range, the Sinamics S120 booksize drives are for winding applications.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Hannover Messe 2021 Scheduled to Open April 12-16

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.