Timken Addresses NVH Requirements in Bearings - September 2020

As NVH technology advanc- es, so do the tools that allow engineers to study, test, and manufacture bearings capa- ble of delivering high-perfor- mance and quality. Everything is subject to variations during the manufacturing process, according to Dr. Desheng (Victor) Li, senior NVH engineering specialist at Timken. The geometry variations, in the form of waviness and surface roughness on ring raceways and rolling element body, are called manufacturing imperfections because all manufactured parts will naturally have some level of variations that cannot be eliminated. When a bearing rotates, the manufacturing imperfections can excite the bearing to vibrate and radiate sound into its surrounding environment. Compared with the manufacturing imperfections, however, the damage such as dents and spalling on bearing components and lubricant contamination are typically the major sources for most significant bearing noise and vibration in applications.

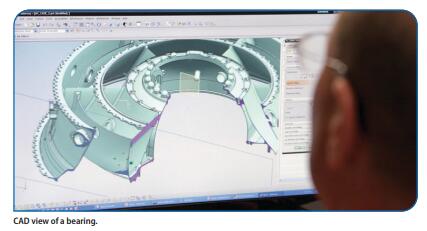

Timken has developed and applied advanced NVH simulation technology to help make bearings quieter and more precise. The following article will discuss how this technology has evolved in recent years and how it might change in the future to meet the increasing demands in the marketplace.

Application Advantages “How quiet is the automobile today versus what we deemed was acceptable 10, 15, even 20 years ago?” asked Brian Ray, chief engineer-industrial at Timken. “With the evolution of the electric vehicle, the entire drivetrain (every piece of rotating equipment) needs to be quieter to accommodate today’s NVH quality standards.” Ray cites the increase in condition monitoring as a significant factor in the growth of NVH tools in 2020. “Engineers are adding more sensors to their equipment while proactively monitoring the signals and the component data. Vibration is typically one of the signals to focus on in condition monitoring,” Ray said. Industries like automotive, paper, and wind have led the way in recent years allowing engineers to examine bearings in diverse applications and environments. Ray said that the NVH data in these areas has led to educational and training opportunities and prepared Timken to better understand how to keep bearings running at the highest and most efficient levels. “Vibration needs to be considered for all machine tools—whether it’s a grinding, milling, or drilling process— in order to create tighter part tolerances,” Li added. The changing requirements in the automotive industry will lead to new NVH tools and resources as more hybrid and electric drivetrains replace the internal combustion engine. “In many cases, customers are concerned about noise-causing vibration that could lead to performance challenges in the larger system,” said Li.

The vibration of rotating equipment can also impact the performance and appearance of the finished product as well. “Another example is the flat rolling of products in the metals industry. Any variation or vibration of the rotating rolls can translate into the finish rolled product, making it visually unacceptable. Applications like automotive body panels and appliances are sensitive to surface variations. Timken has helped our cold-mill customers to solve mill chatter issues so that they can produce aluminum sheets qualified for automotive applications,” Li added.

Bearing NVH Research There are four major driving forces behind NVH research. The first one is the increasing demand for quiet products, such as passenger cars and home appliances, from consumers; the second one is that vibration can affect the quality of the product produced by a machine such as machine tools and cold mill stands; the third one is the tightening government regulations on environmental and workplace sound levels; the fourth one is that some customers use bearing sound and vibration as an indicator of bearing quality and life. Although noise and vibration can be an indicator for bearing damage, there is no solid scientific evidence yet to support the correlation between the sound and vibration generated by typical manufacturing imperfections and bearing life. “The challenge is to design bearings that not only meet performance requirements, but also can be manufactured with a competitive cost,” Li said. Without simulation software, engineers are forced to go through multiple iterations by making the physical prototypes, putting them on a test rig, and measuring the NVH. The process lengthens product development time and increases cost. “Historically, I would say physical testing has been the benchmark and industry standard for measuring and trying to improve the NVH performance of bearings,” Ray said. “In order to prove the performance increase, you have to physically test the bearing and then review the data with your customer.”

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Baldor Enhances Same-Day Gearbox Assembly Operations

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.