Heavy Industry and Smart Technology

The phrase conjures images of mines and steel mills, of huge caverns underground, of cavern-like factories, of old-line companies operating heavy-duty machines for high-torque work.

That’s the image of heavy industry.

Today, though, there’s also another image. It’s of an operator walking a steel mill’s floor, looking at his smartphone or his tablet. He’s not on break, though. He’s working. He’s using his phone to look at real-time data about the mill’s machines. He’s using the Internet to check that the machines are operating smoothly and to see whether any potential problems have been detected and diagnosed.

With the Internet, he can check without being in a control room or on-site or even in the same state. He can check from anywhere in the world.

Today, in heavy industry, more and more machines can transmit their data in real time to the Internet. This ability comes from smart technology, specifically from sensors that 1) can access complex software to mimic human decision-making and 2) can access the Internet. The smart technology is being added inside the machines to critical components, like power transmission (PT) components (gears, bearings, couplings), to reduce downtime — including unplanned downtime — in order to increase productivity.

Heavy Industry: Continuous Operation

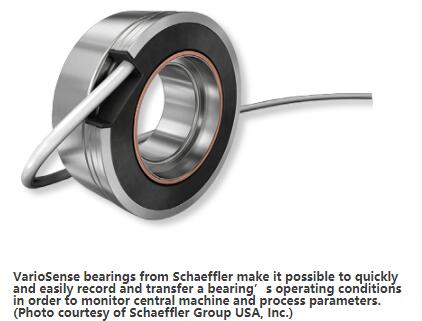

For companies operating in heavy industry, the cost of unplanned downtime is extremely costly. In some cases it can mean the difference between profit and loss for an operation. “To be profitable, they need to minimize their unplanned downtime,” says Mike White. “This is why Schaeffler is actively developing intelligent bearing products. Bearing reliability is often critical to the performance of their operation. By integrating an intelligent sensor to measure temperature, vibration or force, directly into the bearing, valuable data can be obtained — data which can be utilized for early detection of a bearing problem, allowing the customer to proactively schedule and plan for the maintenance.” says White.

White is director, regional business unit manager for raw materials with Schaeffler Group USA Inc., Fort Mill, SC. The Schaeffler Group is a global automotive and industrial supplier that develops and manufactures high-precision components and systems for engine, transmission and chassis applications as well as rolling and plain bearing solutions for a wide range of industrial sectors.

Running a factory 24/7/365, though, makes it difficult to maintain machinery. Even regular, preventive maintenance means stopping machines so they can be inspected and possible problems can be addressed. A stoppage may be brief, the time needed to take a machine off the production line and put another machine on the line. Or the stoppage may be comprehensive, bringing the whole line to a halt because there is no other machine.

With smart technology, downtime for maintenance work can be reduced by shifting at least some maintenance from a schedule to as-needed. Also, the case for maintenance work — for a stoppage — can be easier to make.

“You have the data to prove that ‘Yes, this is the proper time… to make some inspection,’” says Artur Rdzanek, a global product manager for ABB Ltd., Zurich, Switzerland. Rdzanek’s focus is sensors for ABB’s Dodge mechanical PT components. ABB’s Dodge division makes couplings, enclosed gearing, and bearings and serves many customers in the metals industry, the mining industry, and the oil and gas industry.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Tata Steel backs new global framework for decarbonising heavy industries

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.