Wheel Bearing Failures – how to reduce them during the installation process

According to SKF, errors during the installation process are often the cause of wheel bearing failures. The pre-set wheel end was first introduced in the United States in 1995 with the aim of helping to eliminate premature wheel end failure on trucks and trailers. This soon became a popular solution for the North American transport industry, and led SKF to begin working on a similar solution called EasySet in 2008.

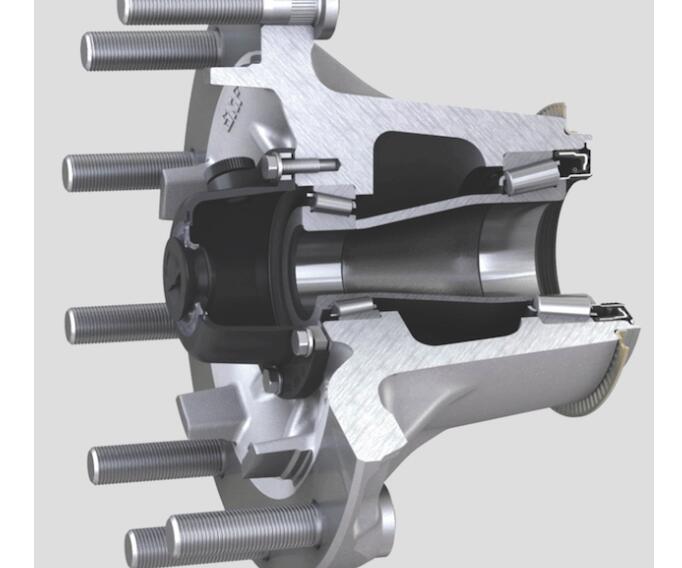

SKF refined its product by adding a spacer between the bearings, with the entire assembly manufactured in-house. The precision-machined spacer is made from high-strength alloy to precise tolerances. This eliminates the need for manual end play adjustment.

Since 2002, the SKF Scotseal PlusXL has also been its primary wheel seal. Its Hydrogenated Nitrile Butadiene Rubber (HNBR) construction is ideal for frequent braking applications. The SKF Scotseal PlusXL also has a high heat tolerance, is compatible with synthetic lubricants, has excellent exclusion properties, even in harsh conditions and features a hand-installable design.

SKF also supplies an all-inclusive rebuild kit that provides all of the necessary components for servicing the pre-set wheel end.

All-in-one rebuild kits

SKF rebuild kits contain specific, tighter toleranced and tapered bearing sets, SKF Scotseal PlusXL wheel seal, SKF TF hubcap (if applicable) and a precision machined bearing spacer.

The SKF TF hubcap is constructed from lightweight DuPont Zytel, which is stronger than aluminium. This material is designed to resist damage from impact, chemicals, UV and the environment. The embedded, solid aluminium ring distributes an even, leak-proof load against the hub, while the cloud-free window is fusion-bonded to the body, without any screws, meaning there is no need to worry about screws loosening.

While SKF asserts that it is possible to remove the spacer and rebuild the pre-set wheel end with individual components from various suppliers, the SKF rebuild kit offers a simple solution designed to reduce fleet downtime, offer easier installation and longer service life.

Unlike off-the-shelf components, all of the kit’s parts are manufactured to SKF specifications. Regardless of axle type, installation follows the same procedure, with no need for complicated torqueing or the use of a dial indicator.

As the kit meets the exact specifications of the original PreSet system components, the rebuilt wheel-end delivers the same kind of reliability and performance.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Ringfeder Couplings Offer Concentricity for Precision Applications

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.