Next-gen battery cells connection and monitoring for e-mobility

As an industrial partner Mersen supports the European project LEVIS with the development of busbars for improved energy management. LEVIS, a project funded by the EU with € 4.9 million, is a consortium of 13 partners from seven countries aimed at developing lightweight components for electric vehicles using an ecological design and closed-loop approaches. One of the basic problems of electric vehicles is the weight of the batteries, for which automotive manufacturers and suppliers have to offset on other vehicle components. The lightweight technologies to be developed in the LEVIS project are supposed to improve vehicle efficiency with respect to kWh mileage and vehicle range, while reducing environmental impact.

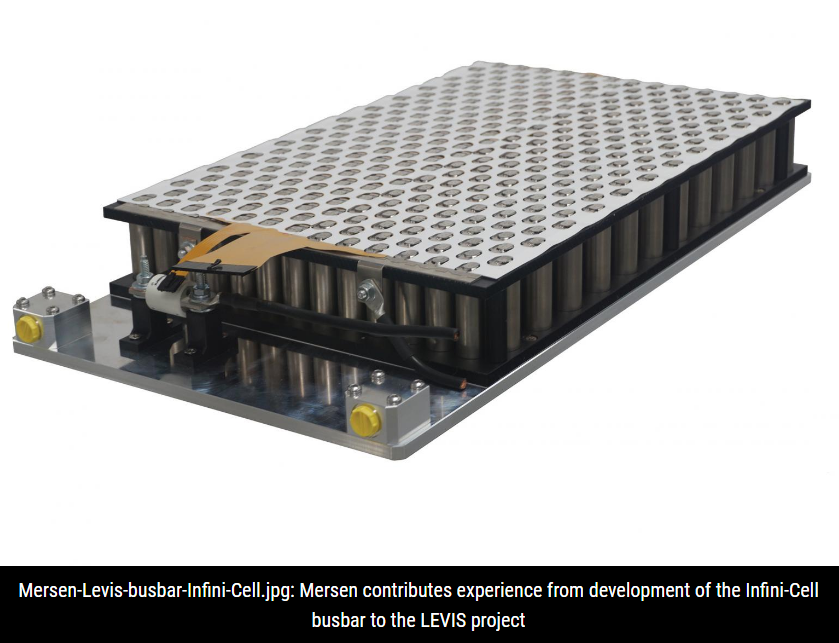

Mersen’s role in this pioneering project is to provide expertise for improving the battery component. With 35 production locations worldwide, the company has invested heavily in research and development in the past – especially in areas with high potential, such as electric vehicles. For the LEVIS project the plant in Angers, France, which specializes in busbars and electrical protection, can draw on its experience in the development of the Infini-Cell. The laminated and extremely thin single-layer busbar with inserted contacts for battery assemblies is very versatile: It connects not only the battery cells, but also monitors their temperature and voltage, prevents wiring errors and offers protection against chocks and vibrations. Infini-Cell is an important advancement toward reducing the space required for battery assemblies without compromising the efficiency or modularity of the power systems.

Knowledge transfer for the future

Besides Mersen, other partners in the project include Instituto Tecnológico de Aragón (ITA) in Spain and the Steinbeis-Europe Center of Steinbeis Innovation gGmbH (SEZ) in Germany. Together, these enterprises are advancing the research and development of innovative materials. Mersen also hopes that the project will serve as a forum for knowledge transfer with respect to innovative materials and reusability. The consortium plans to demonstrate on a large scale the technical and economic feasibility of the alternatives developed in the LEVIS project and to introduce the innovative components on the market.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Lightweight manufacturing in the rail industry

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.