3D-printed part re-scaling tool

Recognizing that all 3D printed parts shrink or warp during the printing process, Riven is introducing a new re-scaling tool that makes it easy to print parts more accurately. Riven’s software automatically computes re-scaling factors as compared to the original CAD. All processes, from FDM through metal 3D printing, can be made more accurate with quick 3D re-scaling. Unlike checking limited dimensions with calipers or a CMM, Riven uses a full part capture to compute an optimal solution based on the entire part shape to produce a more accurate result.

It takes only minutes for Riven’s quick re-scaling tool to create results with clear indications of the location and degree of variance from the intended design.

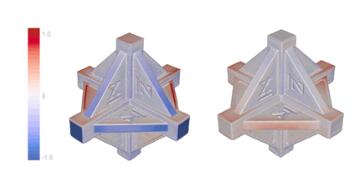

Quick re-scaling result on the left for a first FDM part clearly shows the problem areas. After applying Riven’s re-scaling factors, the CAD-compare result for the second printed part on the right shows that it is more accurate with deviations reduced significantly in critical areas.

Once Riven’s software has checked a test part, new parts can be quickly adjusted using the established re-scaling factors. This technique can be used for FDM, resin-based printing, powder bed fusion, and most metal 3D printing.

New parts printed with the benefit of Riven’s re-scaling factors are more accurate on the first try. The part shown below had deviations relative to the CAD model reduced by a factor of 4.

Fast 3D re-scaling data can save hours, iterations and costs and produce significantly more accurate parts. With only a few minutes for a quick scan and automatic CAD-compare, Riven keeps your projects running smoothly even when you change materials, settings or print in a different location in the print volume. Riven’s re-scaling tool can even be used to calibrate the entire build volume for binder-jet and other professional machines.

For more information about Riven’s 3D re-scaling software capabilities as well as the company’s Push-button CAD-Compare you can share, Digital Go/No Go, Click-to-Measure, and Automatic Scan-to-CAD reverse engineering software, visit https://riven.ai to schedule your personalized live demo.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.