AI Inspect Software

Mitutoyo America Corporation has released the new AI Inspect Software to its overall lineup of software solutions. Intended for use in determining defects in multiple applications, Mitutoyo AI Inspect is a standalone software product designed to assist customers with next generation visual defect analysis.

Key features:

Multi-modular Design: The software features two distinct modules: Training Module and Runtime Module.

Training Module: The main module of the software contains functionality to allow users to develop Inspection routines for automated implementation of defect detection using image sets. Methodologies include:

Project Management of Image Sets: Importation, organization, and storage of user defined inspection projects.

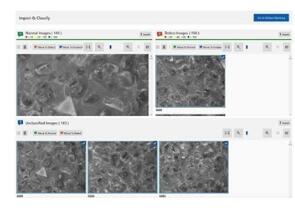

Import and Classification: Integrated tool sets and techniques for loading and classifying both normal (good) and defect (bad) image sets.

Defect Marking: A simplified user interface for the operator to mark-up/highlight defects on images.

Training Setup: Allows the operator to perform a wide range of tasks, including training mode with Testing and Analyzation and Optimization of defect detection models. Additionally, the Image Augmentation section allows operators to apply advanced techniques to the inspection models such as Brightness, Noise and Focus to reduce the influence of typical image aberrational factors that may influence the accuracy of training model.

Training: Provides status for the operator to visualize the progress and success of the training sequence.

Results and Thresholds: A graphical GUI that allows the operator to review number of predictions related to the trained model. These include image classifications and predictions, pixel predictions and defect size thresholds, and the overall model prediction of normal, uncertain, defect and misclassified trained model components.

Deploy: Publish the model for Inspection. Additionally, the ability to publish the model and provide a unique identifier completes the entire deployment process.

Runtime Module: The Runtime Module allows trained AI module to be incorporated into an inspection system. Included in the Runtime module model is the inference testing application that allows review of the AI model for sample testing on new images.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.