Schaeffler Introduces OPTIME in the United States and Canada

Schaeffler is launching its acclaimed OPTIME condition monitoring system in the U.S. and Canada. OPTIME is an efficient, easy-to-use and low-cost solution designed specifically for the comprehensive condition monitoring of all balance of plant assets across entire manufacturing facilities.

Due to cost considerations, permanently installed vibration-based condition monitoring systems are typically used only for production machines that are directly process- or quality-critical. In fact, within the process manufacturing and automation industries, it is not uncommon for up to 95% of all assets in a production facility to be either totally unmonitored or monitored only periodically by means of route-based, manual measurements. “With OPTIME from Schaeffler, however, comprehensive and automated condition monitoring is now a cost-effective proposition for reliability personnel and facility operators,” said Frank Mignano, Schaeffler Americas manager for condition monitoring and Industry 4.0 service solutions.

Automated data analysis – powered by Schaeffler expertise

OPTIME is an easily scalable condition monitoring system that consists of wireless, battery-powered vibration sensors, a cellular gateway and an app to visualize the resulting data. This information, which is captured by the sensors, is analyzed using proprietary algorithms that draw on Schaeffler’s technical expertise, its extensive library of physical models developed and refined over many decades, and the experience in condition monitoring that Schaeffler has built up in the course of its bearing servicing operations.

OPTIME is designed to provide advance warning of potential damage to machines such as electric motors, fans and pumps. It also offers early notification of imbalance, misalignment and loose-fitting components. The OPTIME mobile app displays trends in graph format and visualizes the severity of incidents using traffic light colors, alarm states and other information. Assets can be grouped according to the user’s requirements, and their condition can be presented in a range of user group-specific views. With OPTIME, in-house maintenance personnel and external service contractors receive specific recommendations regarding the steps required to remedy any issues, enabling them to easily plan their maintenance activities, manpower requirements and spare parts procurement in a timely and cost-effective manner.

Quick and easy setup

OPTIME can be installed and put into operation without any prior condition monitoring expertise. This means that several hundred measuring points can easily be set up in a single day. Vibration sensors are attached to the monitored assets by means of screws or adhesive, after which they are activated using the accompanying app that connects to them via near-field communication (NFC). All installed sensors communicate autonomously with each other and the gateway, thereby forming a dedicated mesh network that ranks among the most reliable and energy-efficient types of IoT networks in use in industry today.

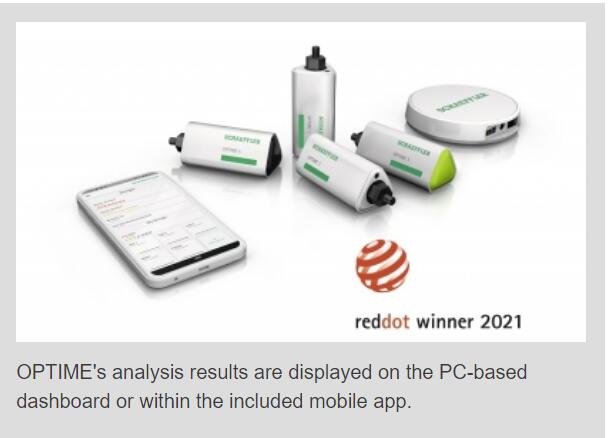

The sensors in OPTIME’s mesh network capture and transmit seven key performance indicators, including six different vibration readings plus temperature, via the gateway to the Schaeffler IoT Hub. The Schaeffler hub analyzes the data, and the results are displayed on the PC-based dashboard or within the included mobile app, the latter of which supports a broad range of devices commonly used by maintenance personnel and plant operators. Alternatively, the diagnostic results can be made available for integration into the customer’s own IT environment via a REST API.

The ideal complement to existing walk-around systems

OPTIME is designed to complement users’ existing condition monitoring programs by collecting 100% of the data generated by a facility’s machinery, and then automatically identifying those assets that are experiencing performance issues. OPTIME also provides more accurate diagnostics than most wireless online condition monitoring systems, thanks to its complex, proprietary algorithm-based analytics. Moreover, OPTIME’s compact size, wireless design and ease of installation enable it to be used on a multitude of assets for which permanently installed condition monitoring was previously not commercially viable. This makes OPTIME the first condition monitoring solution capable of providing a machine status overview that is truly comprehensive and encompasses all subsystems and auxiliary assets. This is important, because monitoring the condition of all assets within a manufacturing operation is fundamental to the reliable prevention of unplanned machine downtime and plant shutdowns.

2021 Red Dot Design Award winner in two categories

OPTIME was recently honored with the prestigious 2021 Red Dot Design Award in the “Smart Product” and “Industrial Design” categories for its outstanding product design, functional configuration and high level of innovation. According to Dr. Stefan Spindler, CEO Industrial of Schaeffler AG, “Our passion for technology and innovation is a key part of Schaeffler’s DNA. The fact that OPTIME received this coveted award proves that we can successfully expand our portfolio of solutions with digital services that prioritize the benefit to our customers.”

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.