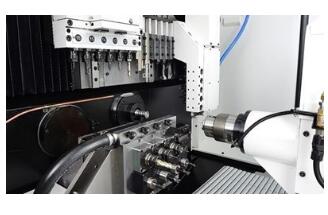

8-axis Swiss mill/turn center

The GENTURN-52CS Y2 is a 2” bar capacity 8-axis Swiss mill/turn center featuring a sub-spindle and dual C & Y axes for the production of complex work in just one handling. There is no guide bushing in this sliding-headstock machine which simplifies setup and reduces job expenses and setup time.

Ample tool stations are provided to get the work done efficiently in just one operation with 33-tool positions and 13-driven tools included. Twenty tool stations service the front side work and an additional 13-backworking tool positions are all standard! The 20 front side tool positions consist of: 6-live cross tools, 3-live axial tools, 6-turning tool stations, and 5-ID tool stations, all in a quick access gang configuration to reduce tool-to-tool time. The Counter Spindle has 13-tool stations including: 4-axial driven stations with 4 live tool holders included. An additional 4 driven tools can be plugged into the sub-spindle tool block as needed. Also 9-I.D. stations are included; 4-I.D. stations from the dedicated sub-spindle tool block, and 5-I.D. stations shared from the backside of the main spindle tooling bridge.

The GENTURN-52CS Y2 CNC Swiss is a very robust and rigid machine with a heavy ribbed torque-tube box casting. The machine weighs over 13,800 pounds making it the heaviest machine in its class! Both Main and Counter Spindle feature accurate “dead-length” gripping and feature a high-performance C-axis with full contouring and 360,000 radial positions (0.001-degree resolution). C-axis operations facilitate engraving and milling highly complex part details. The 51mm (2”) bar capacity spindle runs up to 6,000rpm and the rapid travers rate is 1,181ipm for fast efficient production.

The introductory special value package price is $159,990 and includes an impressive list of standard features that cost extra on other machines. Included items: oil mist collector, parts catcher, parts conveyor, finished parts collection basket, chip conveyor, wheeled chip cart, subspindle programmable air blast, collet oil flush, finished parts ejector with parts eject confirmation, cutoff confirmation, automatic power-off, air-conditioned electronics cabinet, dual-coolant pumps with dual chip filtration and coolant flow confirmation monitoring. Barloader interface and connector plug and 6-ER-20 collet extensions are also provided as well as operator and programming training.

The GENTURN-52CS Y2 features and capabilities compare favorably with conventional twin-spindle, twin-turret lathes costing twice as much, especially by the time 13-driven tools are added to the invoice. The chip-to-chip time on the GENTURN is always faster and the tool count is greater making the GENTURN a far more profitable solution for 2”, and under, bar work.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Harsh environment controller, couplers

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.