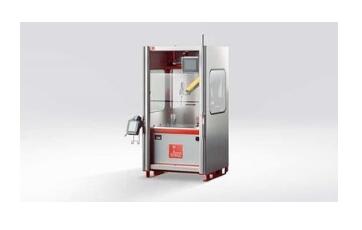

Multifunctional automation cell

In automated production processes, high process reliability, convenient handling and some flexibility are required. The multifunctional cell from DOPAG meets exactly these requirements. It features an autonomous robot system, in which all standard application systems can be integrated. The multifunctional cell is suitable for the metering and application of single and dual-component adhesives, sealants, potting materials, and lubricants. The process technology for the pre-treatment and posttreatment of components – such as plasma pre-treatment or various curing systems – can be integrated easily.

The multifunctional cell is easy to use and offers high flexibility. The workpiece carrier can be replaced as required. It can be changed during production in just a few steps. A single workpiece carrier pick-up is optionally available. An optional workpiece query also increases process reliability. A safety door or swing door for equipping the system, an integrated waste container and a pre-programmed regeneration position ensure safe, convenient operation.

Pre-installed software programs ensure simple operation

No robot programming knowledge is required to set up a new product. All necessary parameters can be configured freely. The robot positions can be entered in a table in the control panel. The robot then processes each point entered one after another. For each operating point, various parameters such as volume flow, metering quantity and pause time can be set individually. The positions for pre-processing and post-processing functions, such as pre-run, regeneration and rinse, can also be set. In total, 20 programs can be stored. The software tools for rail and pallet applications come pre-installed.

Individual configuration based on customer requirements

The multifunctional cell has a modular design and can be configured individually according to customer requirements, application and the necessary pre- and post-treatment processes. In all applications, reproducible and consistently high product quality as well as high cost-effectiveness and efficiency are guaranteed.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.