Deep learning streamlines material inspections

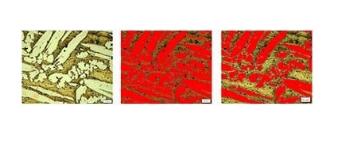

Multiphase analysis of composite materials is a typical industrial image analysis application using deep-learning technology. Left: original image of etched copper. Middle: image segmentation using conventional thresholding methods. Right: deep-learning image segmentation.

Waltham, Massachusetts – Olympus Stream image analysis software now leverages the power of artificial intelligence (AI) to bring next-generation image segmentation to industrial microscope inspections. Software version 2.5 adds Olympus’ TruAI deep-learning technology, enabling users to train neural networks to automatically segment and classify objects in microscope images for a range of material inspections. A trained network can be applied to future analyses for a similar application to maximize efficiency.

Image analysis is a critical part of many material science, industrial and quality assurance applications. However, image segmentation using conventional thresholding methods that depend on HSV or RGB color spaces can miss critical information or targets in samples. Olympus’ TruAI technology offers more accurate segmentation based on deep learning for a highly reproducible and robust analysis.

With the TruAI solution, users can easily train robust neural networks. An easy-to-use interface lets users efficiently label images and run trainings in batches. Networks can be configured with many input channels, trained to identify up to 16 classes, and imported or exported. The solution also offers options to review and edit training details.

The software update also gives all users access to Olympus’ workflow customization services. This team designs tailor-made Olympus Stream workflows to address user-specific application scenarios, challenges, and goals.

Olympus Stream v. 2.4 customers may use their existing license for a free update to software version 2.5.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.