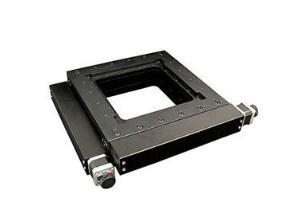

XY alignment stages

High resolution and high repeatability AU200-100x100 Alignment Stages have been released by Optimal Engineering Systems Inc. (OES). The typical applications include: Alignment, inspection, assembly, laser drilling, machining, medical, industrial, semiconductor handling, sampling, testing, scanning, and optical applications in industrial, medical and research applications. Supplied with a standard 4mm-per-turn ground lead screw or an optional 1 mm-per-turn ground lead screw, AU200-100x100 Alignment Stages are capable of 1µm resolution and 2µm repeatability.

Preloaded V-groove and crossed roller bearings contribute to the high precision and stiffness of the AU200-100x100 Alignment Stages. The footprint of these low profile (80mm) tables is 348mm x 348mm and they feature a 188mm x 188mm open aperture. A precise pattern of threaded holes allows for the mounting of tooling and fixtures or an optional solid top plate. Easy access mounting holes allow the XY stages to be easily integrated into new or existing systems.

Stepper Motor driven models feature a resolution of 1µm (achieved with a 20 micro-steps-per-step stepper motor driver). The knobs on the AU200-100x100-01 Stepper Motor series (pictured) can be replaced with an optical encoder for position verification. For closed loop servo operation, high precision, higher travel speeds, and greater throughput, the AU200-100x100-02 series is supplied with Three Phase Brushless Servo Motors and Quadrature Encoders.

Compatible Motion Controllers and drivers are also available from OES and the AU200-100x100 alignment stages can be ordered as a complete plug-and-play system.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.