Predictive maintenance monitoring

Marposs, a world leader in measurement, inspection and test technologies, has announced its new Artis GEMVM system, which monitors vibration, gravity, and temperature values to detect machining anomalies, such as damage to spindle bearings or wear of the drive axles. This makes it an effective solution for predictive maintenance and simple process monitoring, as well as for the detection of collisions and crashes. When a sudden change occurs, the system initiates an alarm in less than 1ms, helping to reduce or avoid the downtime and costs of unplanned maintenance or total failure of machine components.

Predictive maintenance, which provides real-time information from the machine tool, is a more advanced option than preventive maintenance based on previous cases and an estimate of equipment life expectancy. Thus, predictive maintenance contributes to the overall service life of the equipment by preventing early or late replacements. Additionally, it identifies any need for changes in the machine parameters to avoid unwanted events.

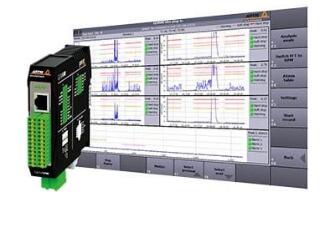

The GEMVM system measures acceleration in up to three axes (depending upon sensor type) with a measuring frequency of up to 5.6kHz and a sampling rate of 25kHz. It has eight definable and selectable operating modes with five freely activatable static alarms. Any events that violate the predefined hard stop limits are logged in the event memory with relevant information for later analysis.

The system comes with the Artis VisuScope diagnostic tool, which is ideal for assuring the quality of new machines and those in operation. Process analyses based upon determined GEMVM data allow historical comparison of machine states, evaluation of damages, and the control after repairs.

The GEMVM can function in a stand-alone mode, running on Windows® (WIN 7/10) machine control panels or Siemens Linux systems (TCU). Or the software can be installed on 7 or 10” industrial PCs from Marposs or any Windows PC (WIN 7/10). Additionally, the GEMVM can also be integrated into a Genior modular monitoring system for process monitoring purposes, delivering the vibration velocity and acceleration to a processing unit for further evaluation.

An autonomous intelligent tool and process monitoring system, Genior Modular provides an automatic real-time image of a current production process. It provides a multi-criteria monitoring strategy that automatically adapts to machining processes, meaning that the system records all relevant signals and sets the limits based on special algorithms. During the following machining cycles, it then adjusts the automatic limits to compensate for changes in tooling and machine. The modular system design enables configuration to dedicated systems or machines as well as the ability to add capability as needed.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.