GE starts testing second XA100 adaptive cycle engine

GE has initiated testing on its second XA100 adaptive cycle engine as part of the U.S. Air Force’s Adaptive Engine Transition Program (AETP). Testing began on August 26, 2021, at GE’s Evendale, Ohio, altitude test facility. This is GE’s final planned prototype engine as part of AETP.

Full-scale prototype engine testing in the AETP program is the capstone of a multi-year technology maturation and risk reduction effort to bring an adaptive cycle engine to full maturity in close partnership with the U.S. Air Force. GE’s first XA100 engine tests began in December 2020, marking the world’s first ever run of a flight-weight three-stream adaptive cycle engine. Tests successfully validated the engine’s ability to deliver transformational propulsion capability to current and future fighter aircraft. Engine prototypes assembled as part of AETP are designed to fit and integrate directly into the F-35.

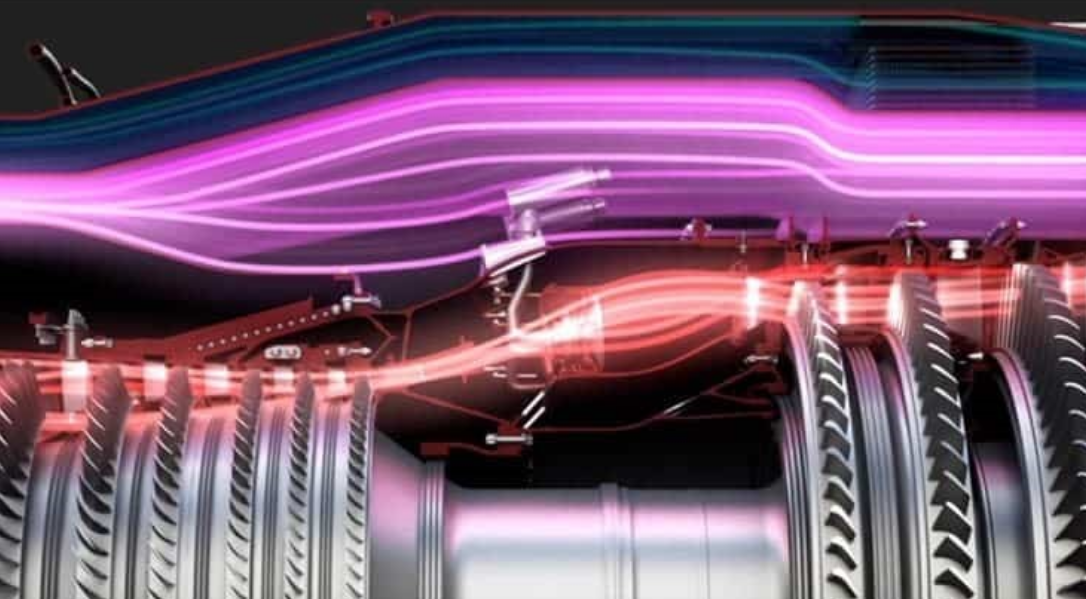

The XA100-GE-100 engine combines three key innovations to deliver a generational change in combat propulsion performance:

• An adaptive engine cycle that provides both a high-thrust mode for maximum power and a high-efficiency mode for optimum fuel savings and loiter time

• A third-stream architecture that provides a step-change in thermal management capability, enabling future mission systems for increased combat effectiveness

• Extensive use of advanced component technologies, including ceramic matrix composites (CMC), polymer matrix composites (PMC), and additive manufacturing

These revolutionary innovations increase thrust 10%, improve fuel efficiency by 25%, and provide significantly more aircraft heat dissipation capacity, all within the same physical envelope as current propulsion systems. The XA100’s improved fuel efficiency provides significant reduction in carbon emissions. The engine will also operate on any U.S. Air Force-approved biofuels.

“The U.S. Air Force and Congress have invested more than $4 billion in adaptive cycle engine development over the past 14 years to mature its associated technologies. We’re confident this phase of the program will significantly reduce risk and prepare GE for a low-risk engineering and manufacturing development program, consistent with Air Force objectives,” said David Tweedie, GE Edison Works’ General Manager for Advanced Combat Engines. “Getting our second prototype engine into the test cell means we’re one step closer to getting this transformational technology into the hands of the warfighter.”

Testing on the second XA100 will allow GE to continue gathering high-quality test data and further mature the engine’s advanced componentry and revolutionary three-stream design. Once first phase testing is complete in Evendale, GE plans to test the engine at the U.S. Air Force’s Arnold Engineering Development Complex (AEDC) to finish out all planned AETP testing activities.

“The Air Force has put a tremendous amount of rigor into the AETP product requirements. We believe we’re delivering on those requirements, and a big reason for that is our close collaboration with the Air Force. Our partnership there has been a critical factor in our success,” Tweedie added.

The XA100 is a product of GE Edison Works, a business unit dedicated to the research, development, and production of advanced military solutions. This business unit has full responsibility for strategy, innovation, and execution of advanced programs.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next MINExpo 2021 Examines Safety, Cost Reduction and Productivity in Mining Sector

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.