High-penetration drilling system

Allied Machine and Engineering’s T-A Pro high-penetration drilling system builds on 35 years of spade drilling success with the T-A (throw away) insert.

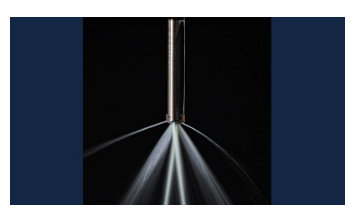

The T-A Pro drill combines material-specific insert geometries, a redesigned drill body, and a proprietary coolant-through system to allow penetration rates which run at speeds nearly 30% faster than other high-performance drills on the market.

Coolant outlets are direct maximum flow to the cutting edge, providing quick heat extraction where it is most critical – even at significantly higher speeds. Material-specific insert geometries produce impeccable chip formation and the drill body incorporates straight flutes redesigned for maximum coolant flow and excellent rigidity.

These design elements combine to extend tool life, create consistent quality holes, and provide superior chip evacuation. As a result, the T-A Pro drill offers machine shops and high production manufacturers a spade drill with incredible speed and a cost per hole averaging 25% less than existing drills.

The T-A Pro drilling system will be available in diameters ranging from 0.4370” to 1.882” (11.1mm to 47.80mm) and is ideal for holes ranging in stub, 3xD, 5xD, 7xD, 10xD, 12xD, and 15xD depths. The drill will be stocked in imperial and metric shanks, with flat and cylindrical variants.

The carbide insert geometries offered initially will cater to the following ISO material classes:

Steel (P) with AM300 coating

Cast iron (K), with TiAlN coating

Non-ferrous (N) with TiCN coating

The T-A Pro drilling system will be available to order from Allied Machine’s distributor partners in October.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.