New acoustic imager launched

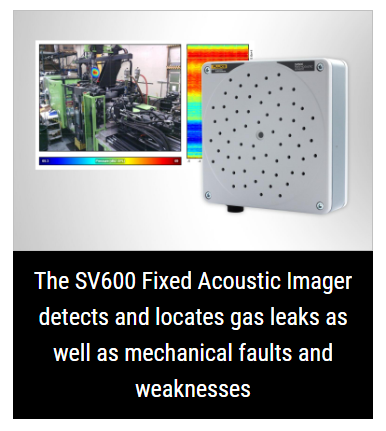

Fluke Process Instruments, a global leader in infrared imaging and thermal profiling solutions for industrial applications, releases its first fixed acoustic imaging solution. The SV600 Fixed Acoustic Imager enables users to detect, locate and visualize air and gas leaks or changes in sound signatures across their process and equipment in real-time before they become costly problems. By using an array of sophisticated sound sensors and powerful SoundMap technology, the SV600 translates the sounds that it hears into a visual representation so users can quickly locate and quantify problem areas.

The SV600 easily integrates with factory systems and can serve as an early warning system that can quickly detect changes across compressors, pumps, pipes, conveyors or across product inspection and quality control processes, and much more with user-defined alarms. Remote evaluation options, meanwhile, help to minimize operator intervention, even in parts of the facility that are hard to reach.

“With automated acoustic imaging that the SV600 brings, maintenance teams can visualize leaks or sound signature changes to factory equipment or assets, and prevent unscheduled maintenance and possible costly downtime, and at the same time improve factory safety by minimizing operator intervention,” says Herman Warnshuis, president, Fluke Process Instruments. “We are excited to bring this new technology to customers across the globe and cannot wait to see how they utilize the technology to detect, locate and visualize sound signature changes or leaks in their process.”

The SV600 can also be used a payload for Boston Dynamics’ agile mobile robot Spot, which takes inspection to the next level. Designed to go where other robots cannot go and to perform a broad number of tasks, Spot traverses large facilities or unstructured terrain to automate industrial inspections, monitor remote or difficult-to-access environments and provide situational awareness in remote settings. With the SV600 payload, Spot can be reconfigured to automate air and gas leak detection, increase maintenance team efficiency, greatly reduce safety risks and reduce energy costs.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.