JTEKT has successfully developed a low-torque, cold-resistant and high-strength hub bearing unit

JTEKT has successfully developed a hub bearing unit with low torque and high sealing performance even in cold regions. We will put the new products developed this time on the global market including extremely cold regions, and contribute to the realization of a low-carbon society.

1. Development background

In recent years, in order to achieve carbon neutrality, the manufacturing environment led by the automobile industry has more than ever needed to reduce energy losses. The low-torque of the wheel hub bearing unit that supports automobile wheels has also become an indispensable technology directly related to fuel consumption.

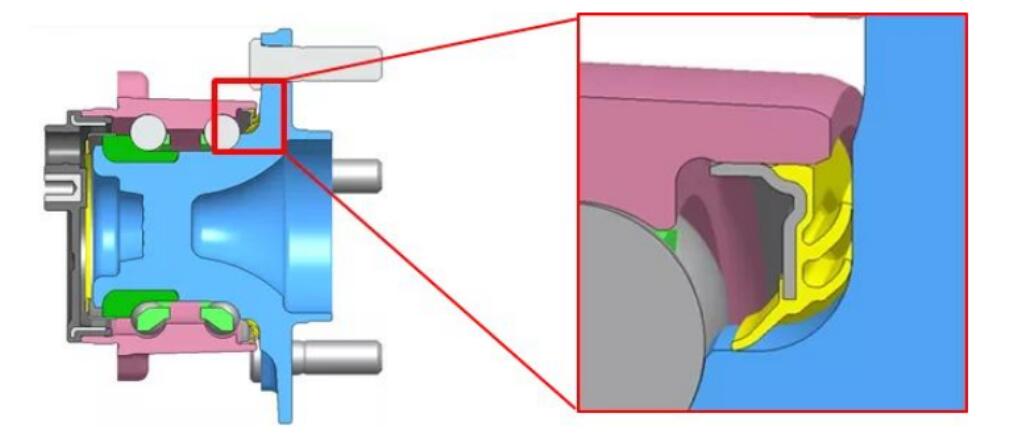

On the other hand, the nitrile rubber used for sealing part accounts for about half of the torque generated by hub bearing unit. It is used as sealing material in hub bearing unit and various fields, but its low friction property is contrary to the physical properties of rubber ( such as strength, heat resistance, wear resistance, etc. ). Therefore, how to realize the two properties at the same time has become a topic.

Generally speaking, nitrile rubber has certain advantages in oil resistance, abrasion resistance, and tear strength, but its cold resistance is inferior to other rubber materials.

With the development of marketization, if the hub bearing unit produced by JTEKT will be used in a harsher environment than the current one, then expanding the use temperature range of the sealing rubber has become an important issue.

2. Features and advantages of the new product

1. Low torque

The technology developed this time to apply rubber to the sealing material has achieved a 10% reduction in sealing torque.

2. High tightness

Because rubber does not lose its elasticity in extreme cold environments below -40°C and can maintain the integrity of the seal, it can prevent muddy water from entering the hub bearing unit even in extreme cold areas such as North America and Russia.

The rubber material developed this time can be used not only in wheel hub units, but also in various industries including other auto parts. JTEKT will continue to contribute to the realization of a low-carbon society.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next A Cost Effective Bearing And Steel Ball Factory HFD Released A Video Introducing Its Factory On The Beginning Of 2021 Dec.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.