New coating method for PV modules

Toshiba has developed a new coating method for the perovskite layer that boosts power conversion efficiency (PCE) to 15.1% for Toshiba’s 703cm2 module, what it believes to be the highest for any large, polymer film-based perovskite photovoltaic module. The innovative coating method for perovskite layer also greatly reduces production time and costs, contributing to a lower cost for solar power generation.

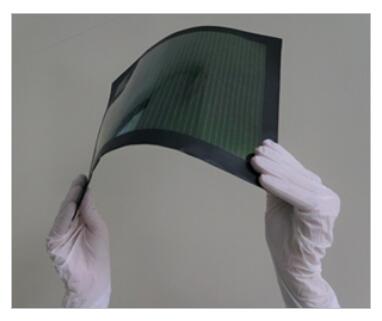

Success in achieving carbon neutrality will require much greater use of photovoltaic power generation, and a significant expansion in locations where photovoltaic modules can be installed. Today’s most widely used photovoltaic modules are made with crystalline silicon and are heavy, and this, plus their rigidity, limits where they can be installed. The polymer film-based perovskite photovoltaic module is an attractive next-generation alternative, as it is thin, light and flexible, and can be installed in locations where it is difficult to use silicon photovoltaic modules, such as low load-bearing roofs and office windows. Recent improvements in the PCE of perovskite photovoltaic modules has brought them to a level comparable to that of silicon photovoltaic modules.

Toshiba’s latest breakthrough is the development of a new perovskite layer coating method. The company previously developed a two-step coating process that first applied a layer of PbI2 (lead iodide) ink to a substrate, followed by a layer of MAI (methyammonium iodide, CH3NH3I) ink, triggering a reaction that formed an MAPbI3 layer. However, this multi-step approach had a low coating rate and often left unreacted sections in the perovskite layer. The alternative is a one-step process that applies MAPbI3 ink directly, but it is not easy to control crystallization of the MAPbI3 and obtain a uniform perovskite layer across a large area. A new coating method that solves these problems was required.

Toshiba has developed a one-step meniscus coating method that uses improved ink, film drying processes and production equipment to form a uniform perovskite layer over an area as large as 703cm2. These innovations halve the steps for deposition of the perovskite layer, and raise the coating speed to 6 meters per minute on a 5×5 cm2 module, a rate that meets requirements for mass production.

Applied to the company's previously reported 703cm2 polymer film-based perovskite photovoltaic modules, the one-step meniscus coating method achieves a PCE of 15.1%, which Toshiba says is the world's highest ever for a polymer film-based large-area perovskite photovoltaic module. This higher PCE and the faster, simplified production process, significantly advance progress toward the commercialization of highly efficient, low-cost, polymer film-based perovskite photovoltaic modules.

Toshiba estimates that the new perovskite photovoltaic modules would generate power equivalent to two-thirds of the annual power consumption by homes in Tokyo if installed on a roof area of 164.9km2, roughly equal to the roof surface area of all buildings in Tokyo.

The firm will continue research on perovskite photovoltaic modules, aiming to increase PCE to 20% or more, and to enlarge the active area to 900cm2, the size required for practical application. The company estimates achieving these targets will cut the manufacturing cost of perovskite photovoltaic modules to 15/W (approx. $0.14/W).

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next New pedestal boom

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.