Spotting The Material Difference

Frederik Tryssesoone discusses stainless steel piping solutions for remote mine sites

Stainless steel piping has a long history on mine sites. The robust, corrosion-resistant material is ideal for mine process piping systems that are designed to provide a long service life.

Lihir Mine has been operational since the mid-1990s, processes up to 15 million tonnes of material per year, and is the fifth largest gold mine in the world. Located in Papua New Guinea – an equatorial country surrounded by ocean – the mine is constantly exposed to humid weather conditions and sea spray, creating an extremely corrosive environment for metals, and an ideal application for stainless steel piping. The mine relies on the long service lifespan of its piping systems due to the remoteness of the site which can complicate and lengthen maintenance schedules.

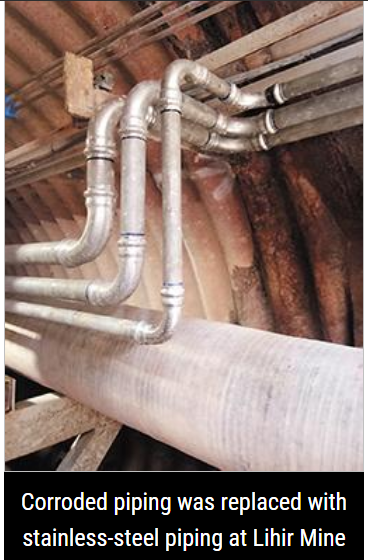

The mine’s US$45 million sustaining works programme included a project to replace existing corroded pipelines with robust, corrosion-resistant stainless steel piping. Victaulic Vic-Press products for stainless steel piping were chosen to provide a high-quality, ASME-compliant piping system. The owner’s and engineer’s key concerns were to ensure joint integrity while increasing the life span of the piping systems.

A Better Way To Join Stainless Steel Piping

In comparison with threading, Victaulic Vic-Press for stainless steel piping requires no skilled labour to operate special equipment. Vic-Press joints are pressed into place with an easy-to-operate hand-held gun. This ease of installation allowed the piping system to be joined by the local labour force and ensured consistent, properly installed joints throughout the project. Furthermore, Victaulic Vic-Press installed six times faster than threading.

Remote Sites Are No Problem

Victaulic representatives worked closely with the Lihir Mine project team; from the feasibility and product selection stage with the engineer, all the way through the bidding stage with contractors. The company also coordinated with the mine’s procurement teams for advanced stock forecasts to ensure its materials would be delivered on time. Despite the remote location, the representatives visited the Lihir Mine site to provide hands-on training to the local workforce in Papua New Guinea, providing complete assurance and peace-of-mind to all stakeholders that the system would be installed correctly and meet ASME code requirements.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Predicting solid surface molten droplet solidification

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.