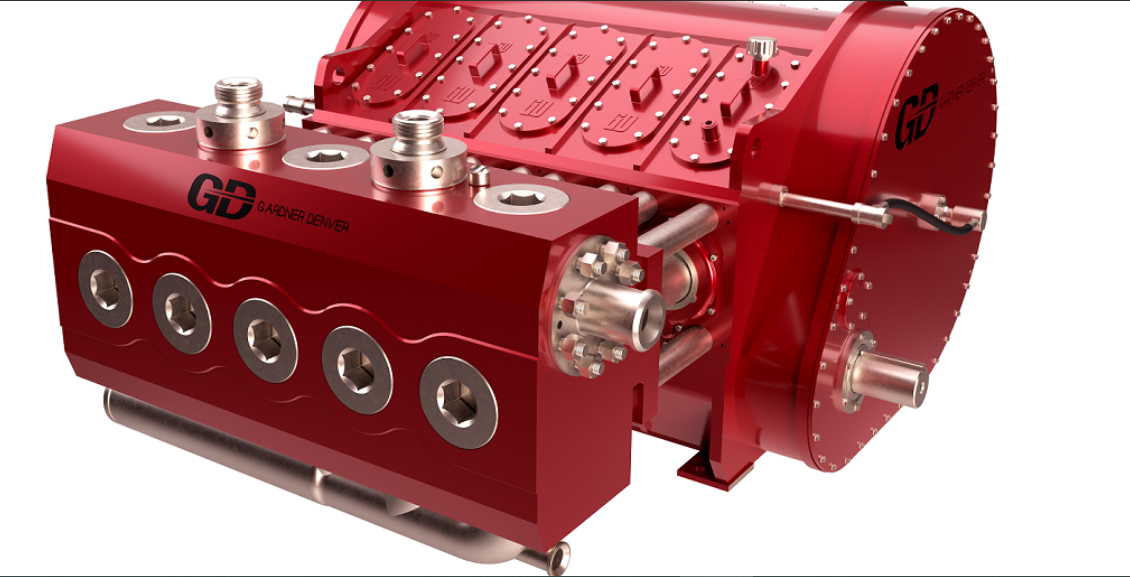

New quintuplex pump

Gardner Denver has announced the new GD 2500Q Heavy Duty Frame (HDF) quintuplex pump, designed to extend pump service life through an optimized power end frame design. The frame upgrade has been developed to increase component thickness and allow for larger, stronger welds, to boost structural integrity.

Today’s pumping conditions have pushed power end frames of all makes to their limits. The upgrade was designed with the aim of reducing stress in vulnerable areas.

The updates include:

Top and bottom skin plates increased in thickness, offering more structural support for nose plate loads.

Main bearing plates have now increased in thickness and protrude between skin plates with larger, stronger welds, reducing overall frame and weld stress.

Stronger support structure for nose plate to reduce deflection around nose place welds.

Significant nose plate weld size increased, reducing stress in critical nose plate joint by more than 20%.

Deep bevelling around outer main bearing plates, giving much deeper weld throat.

Eliminated snap ring bearing retainer and replaced with stronger, bolt-on outer main bearing retainer, giving improved axial tolerances for improved gear timing.

Turner Hall, engineering supervisor, HPS, said, “The GD 2500Q has proven itself as a reliable, durable pump that has stood the test of time. As a result of our commitment to continuous innovation and product improvement, we have now simplified the geometry from our legacy design and made the welds stronger and larger, resulting in longer pump life. These upgrades will save our customers a significant amount of time and expense as they improve the service life of their pumps.”

Edward Bayhi, vice president and general manager, HPS, said, “As units are pumped for longer with heavier concentrations of sand, customers have found it increasingly difficult to get longevity out of their power ends. Gardner Denver’s engineering team stepped up to the challenge with the GD 2500Q HDF and added strength to our legacy design to increase fatigue life and improve manufacturability, both of which are critical in meeting the challenges of today’s harsh frac environments.”

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.