It All Comes Together With Knowledge Transfer

Lessons learnt from tidal energy tripod decommissioning shared

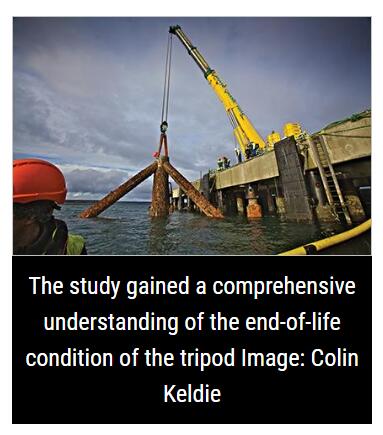

An innovative, collaborative decommissioning project at the European Marine Energy Centre (EMEC) has completed the forensic analysis of a tidal energy tripod.

The study gained a comprehensive understanding of the end-of-life condition of the tripod, assessing the long-term effect of deploying components and systems in the challenging high velocity environment at EMEC’s Fall of Warness tidal energy test site. The tripod had been submerged for approximately 11 years during which two tidal turbines had operated on it.

Significant learnings have been collated and two reports published to provide feedback and design guidelines to the offshore renewable energy industry, enabling developers to minimise decommissioning costs and de-risk future projects.

John Skuse, operations and maintenance manager from EMEC said: “Decommissioning is a critical part of the lifecycle of ocean energy projects, however it’s not yet well explored, as relatively few ocean energy technologies have progressed to the decommissioning stage following long-term deployment.

“It is imperative that decommissioning is managed carefully, including design stages, installation, performance, right through to decommissioning. As the industry continues to develop and mature, the ability to decommission devices efficiently and cleanly will be instrumental in ensuring site utilisation is maximised.”

EMEC contracted Orkney-based marine operations provider, Leask Marine, to remove the tripod foundation from the Fall of Warness test site. The project required continuous innovation by the Leask Marine team during the cutting and retrieval operations. Standard industry equipment used in offshore subsea oil and gas would have been unable to withhold the strong currents. Leask Marine’s engineering team therefore designed and fabricated a new robust cutting tool support frame to hold the tool in place on the pile with sufficient grip to control the turbulent drag forces.

The specifically designed frame had a buoyancy system added to help lift the 140-ton structure from the seabed in one operation. Leask Marine’s vessel then towed the frame and tripod to Hatston Pier in Kirkwall for forensic analysis, final cutting and disposal of parts.

Forensic Analysis

Forensic analysis was carried out by Blackfish Engineering Design, the International Centre for Island Technology (ICIT) at Herriot Watt University, Rovco, Brunel Experimental Techniques Centre, and Brunel Centre for Advanced Solidification Technology.

Forensic examination activities assessed biofouling, corrosion, metallurgic (metal) defects and electrical connector longevity.

The study found that all surfaces exposed to seawater current will be subjected to vigorous fouling. Components that are expected to move, slide, or require clearance in any way must be designed assuming that biofouling will occur on all steel surfaces. Components that are installed for long-term submersion should be designed to account for biofouling end stage communities up to 15cm thick and the additional weight should be factored into lifting operations during decommissioning. Biofouling was markedly reduced where larvae access to surfaces was restricted due to a lack of flow and a lack of nutrient supply.

Stainless steel 316L, titanium and super duplex material have all shown excellent resistance to corrosion, but all of them are susceptible to biofouling.

The study was part of the EMEC-led FORESEA project, funded by Interreg North-West Europe.

Tim Warren, Engineering Director, Blackfish, said: “This decommissioning project has provided really valuable data for engineering designers and project developers of offshore renewable devices. A detailed examination of the biofouling, corrosion and performance of different structures, materials and coatings has provided a great insight into the long term performance of submerged components and how the design can be improved to ensure longevity and performance for their entire lifetime.

“By publishing this project and the lessons learned to the wider offshore renewables industry, it is hoped that future devices will benefit from this by reducing costs and improving decommissioning operations.”

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Sustainable mobility collaboration

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.