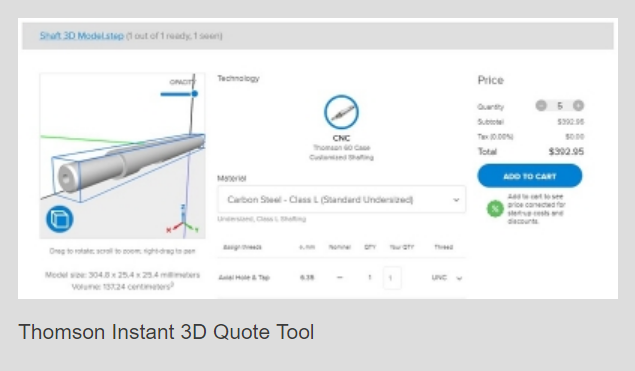

Thomson Linear Offers Online Tools for Motion Control Components

Thomson Linear offers a guide to selecting, configuring and ordering motion control componnets online.

Linear motion components such as bearings, shafts, actuators and slides are heavily utilized in many types of industrial machines, so the more that engineers can streamline component design, configuration and ordering, the more they can lower their production costs.

A typical palletizer, for example, might use up to 20 motion control components, which must be thoughtfully integrated with other machine parts. Going through the steps to specify even one component, such as a shaft, can take hours. Specifying the remaining motion control components extends the process from hours to days, and once you’ve integrated all components into a shipment-ready palletizer, you’re looking at weeks or even months.

New online tools, coupled with online libraries of pre-selected and tested component specifications, simplify integration across all machine design phases, reducing selection, configuration and ordering time to mere minutes, with shipment following as quickly as the next day.

Buyers of consumer products such as laptop computers or home entertainment electronics have long enjoyed the benefits of online selection, configuration and ordering. However, e-commerce for products such as motion control systems has lagged behind, mostly due to the scope and complexity of their specification options.

Traditional selection technology often drives users down multiple selection paths to unprioritized results. For example, a machine designer needing a prototype or sample of a motion component may have to sort through hundreds of options before getting to an optimal part, which can take hours.

This online specification process is especially challenging for a designer who is selecting components for parts of an application that may not fall under their core expertise. For example, if they search for “linear bearings,” they might get hundreds of results for die sets, linear guide rails, linear shafting, support rails, sleeve bearings and square bearings. They would still then be required to sort through, compare and analyze the results before narrowing down to the most ‘suitable’ component that meets their needs.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Renewable Lubricants Introduces Bio-Ultimax 1000

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.