FANUC Provides Predictive Maintenance Software for Drive Systems

Downtime is the enemy of profitability in manufacturing, which is why FANUC has introduced a new Industrial Internet of Things (IIOT) software designed to prevent production problems before they happen. AI Servo Monitor uses artificial intelligence to predict possible failures of the drive systems for FANUC servomotors and spindle motors.

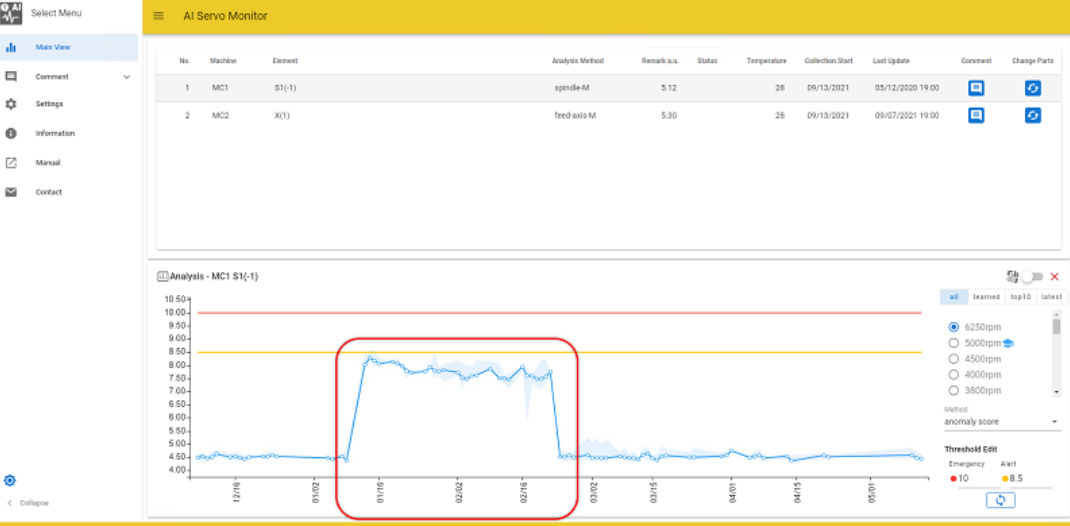

AI Servo Monitor, in conjunction with MT-LINKi through machine learning, analyzes the daily performance of machines equipped with FANUC CNCs. Daily data is displayed in intuitive graphs which allows users to easily monitor abnormalities on these machines. Artificial intelligence automatically creates a baseline model of the machine while running in a normal state. An “anomaly score” developed expresses a difference in the baseline model and the daily recorded values. On a web interface, users can easily see the anomaly scores in a graph. Plus, email notifications can be issued if this value exceeds the predefined thresholds.

“The power of IIOT software is that it detects a failure before it happens, not after,” says Jon Heddleson, general manager of factory automation for FANUC America. “Predictive maintenance is key in preventing unexpected downtime. FANUC’s AI Servo Monitor helps ensure that production keeps running smoothly.”

MT-Linki is FANUC’s machine status monitoring and data collection software that connects shop floor equipment, including machine tools, robots and PLCs. MT-Linki monitors, collects, and presents data in color-coded graphical representations of the factory floor to provide more information about manufacturing processes as well as historical data. Non-FANUC CNCs, PLCs and various sensors can be connected using MTConnect or OPC-UA protocol.

Information presented via MT-Linki enables data-driven business decisions to optimize operations through enhanced maintenance capabilities such as scheduling memory backups, presenting alarm/operator history, and monitoring the status of memory backup batteries, cooling fans, motor temperatures, etc.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.