Trelleborg launches ultra-low friction bearings for offshore oil, gas operations

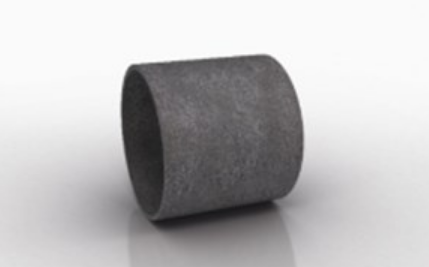

Trelleborg Sealing Solutions announced the launch of Orkot C620, an ultra-low friction bearing material with five times the compressive strength of other Orkot materials for offshore, oil and gas and marine applications.

A high-specification thermoset composite, Orkot C620 meets the requirements of the most demanding high-load applications. Though strong and light, it withstands high loads and stresses over a long service life.

Mark Hampton, Product and Innovations Manager, said, “Orkot C620’s optimized properties provide customers with a step change in composite bearings, offering a unique combination of ultra-low friction and a compressive strength of 470 MPa, five times the strength of standard Orkot materials. It is both stronger and has better friction characteristics than competitor composite materials, and can even challenge many metallic bearings for strength, offering industries such as aerospace the lighter, lower-friction solutions they increasingly demand.

“Featuring a strong glass fiber backing with a low-friction Orkot lining, it builds upon regular Orkot composite formulations with a unique compound where the properties of the different layers increase load capacity and strength. It does this without compromising weight while reducing friction and eliminating maintenance to maximize efficiency and service life.”

Because of its unique characteristics, Orkot C620 is an attractive solution across a wide variety of sectors with demanding high-load applications, including offshore, oil and gas and marine applications.

For offshore wind turbines, it reduces maintenance requirements for deep-sea mooring connections and provides electrical isolation, enhancing corrosion resistance while resisting high loads from rough ocean currents. In wind turbine pitch cylinders it provides a very low coefficient of friction, allowing smooth operation at high loads and low speeds.

For floating production, storage and offloading (FPSO) mooring infrastructure, Orkot C620’s advantages include low wear rates in fairhead and tensioner applications, and low friction and minimal stick-slip, making it ideal for slow movements in FPSO turrets and swivel stacks. In mid-water arches, it is strong enough to withstand high loads on supporting risers, cables and umbilicals.

A number of applications for cranes also benefit from the properties of Orkot® C620. The material’s inherent degree of flexibility allows it to compensate for shaft misalignments and be customizable to the design envelope of the application. In slewing bearings it provides excellent stick-slip properties to ensure smooth movement of the boom and load.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next AutomationDirect Offers Toshiba EQP Global SD Severe Duty Motors

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.