Can the inner and outer rings of the bearing cooperate with rotating parts at the same time?

Can the inner and outer rings of the bearing cooperate with rotating parts at the same time?

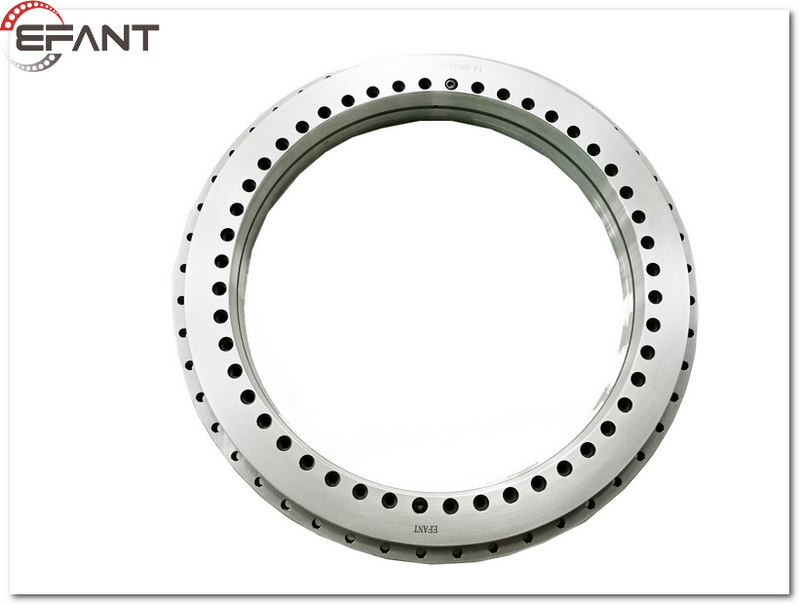

Yes, in a rotating system, both the inner and outer rings of a bearing can cooperate with rotating parts simultaneously. Bearings facilitate relative motion between two parts, allowing them to rotate with respect to each other while minimizing friction and wear. Here's how the inner and outer rings work in collaboration with rotating parts:

1.Inner Ring:

The inner ring is mounted on the rotating shaft of the machine or equipment.

As the shaft rotates, the inner ring rotates along with it.

2.Rolling Elements:

Spherical roller bearings, like many other types, have rolling elements (such as rollers) positioned between the inner and outer rings.

These rolling elements allow smooth and controlled rotation of the inner ring relative to the outer ring.

3.Outer Ring:

The outer ring is typically mounted in a stationary part of the machine or equipment, such as a housing or frame.

While the inner ring and shaft rotate, the outer ring remains stationary, providing a fixed reference point.

4.Functionality

The rolling elements, located between the inner and outer rings, distribute the load and reduce friction during rotation.

This design allows the inner and outer rings to work together, enabling the rotational motion of the shaft while maintaining stability and support.

5.Application:

In various machinery and mechanical systems, spherical roller bearings are commonly used to handle radial and axial loads, making them suitable for applications with both rotational and axial movement.

6.Axial and Radial Loads:

Spherical roller bearings are designed to accommodate both axial (thrust) and radial (perpendicular to the shaft) loads, making them versatile for a range of applications.

It's important to note that proper installation, alignment, and lubrication are essential for ensuring the effective cooperation between the inner and outer rings with rotating parts. Additionally, regular maintenance and monitoring of the bearing condition are crucial to prevent issues such as misalignment, wear, and premature failure. Always follow the manufacturer's guidelines and recommendations for the specific bearing type and application to ensure optimal performance and longevity.

Contact

Company:Luoyang EFANT Precision Bearing Manufacturing Co. Ltd

Address:No. 9 Jingjin North Rd, Luoxin Development Zone,

Xin'an County, Luoyang City, Henan Province 471003, China

Tel:86-379-80887690

export@efindbearing.com

https://www.efindbearing.com/contact-us

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next What are the methods for installing spherical roller bearings?

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.