Mahle Presents Electric Drives at CES 2024

Mahle (Booth 55439-24) will feature products focusing on electric drives and intelligent charging at CES 2024.

"Electrification is the focus of the future for Mahle as we continue to position ourselves as a systems-expertise champion in e-mobility," said Peter Lynch, vice president of sales and application engineering and president, Mahle Industries, Inc.

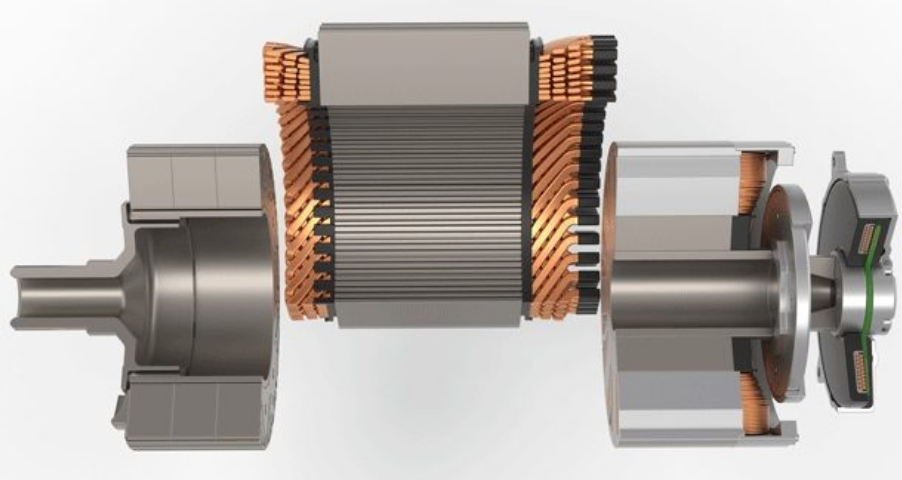

A new technology kit for electric motors on display at CES combines the advantages of Mahle's benchmark SCT (Superior Continuous Torque) and MCT (Magnet-free Contactless Transmitter) electric motors. The "perfect motor" combines permanently high peak power, contactless and thus wear-free power transmission, the absence of rare earths, and maximum efficiency.

With its bionic battery-cooling plate, Mahle has achieved a technological leap forward by using nature as a model. The company's all-new positioning system for wireless charging was recently chosen as the global standard technology by SAE International.

Mahle's technology kit for electric motors featured at CES 2024 combines the advantages of the company's benchmark SCT and MCT electric motors. With this unique technology toolbox for electric motors, Mahle can offer its customers customized electrification solutions for any vehicle class, application, or even brand philosophy.

The MCT and endurance champion SCT electric motors are among the latest innovations from the German automotive supplier in the field of electric drives. Dispensing with rare earths in MCT technology not only makes production more environmentally friendly, but also brings advantages in terms of costs and raw- material security. It is particularly efficient at almost all operating points.

The MCT electric motor shows its efficiency advantages to the full, especially in those areas that are frequently used in real road traffic. The MCT electric motor is characterized by high durability because the necessary transmission of electric currents between the rotating and stationary parts inside the motor is contactless and thus wear-free. The motor therefore is maintenance-free and suitable for a wide range of applications.

With the SCT electric motor, Mahle currently has the most enduring electric motor in its range. The traction motor can operate at high power for an unlimited period of time. This technological leap was made possible by a new cooling concept. Innovative integrated oil cooling not only makes the e-motor robust, but at the same time also allows the waste heat generated to be used in the vehicle's overall system. The new e-motor is unrivaled in its small size, light weight and efficiency. The extremely compact design also results in a material-cost and weight advantage; a lighter motor requires less material in production and at the same time increases the possible payload in commercial vehicles.

Also on display is a Mahle-developed wireless-charging positioning system that allows an electric vehicle to be simply, reliably and precisely aligned above a charging coil in the floor. SAE International, the US-based standards developing organization for engineering professionals, has chosen the Mahle positioning system as the global standard solution for wireless charging. The cross-manufacturer solution from Mahle paves the way for the comprehensive and rapid market launch of this attractive alternative to wired charging for batteries and for electric and hybrid vehicles.

Essential for battery electric vehicles is heating and cooling in the car – so-called thermal management. Using nature as a model, Mahle has achieved a technological leap forward with its new battery-cooling plate. Mahle's battery- cooling plates ensure fast charging, long cruising range and long service life for sensitive lithium-ion batteries, making the complete system significantly more efficient with up to 20 percent more battery life. Mahle was able to increase cooling performance by 10 percent and reduce pressure loss by 20 percent. As a result, the battery can be reliably and homogeneously kept within the necessary temperature window. It thus becomes more efficient and can reduce charging time.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next EFANT factory will participate in the METALLOOBRABOTKA in 2024

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.