Particle-Based CFD Study of Lubrication in Power Transmission Systems Using Local Refinement Techniques

In the field of mechanical engineering, addressing challenges related to energy efficiency, raw material consumption, and environmental impact has become increasingly critical. Industries are constantly pushed to develop innovative products and optimize existing ones to comply with strict regulations governing power consumption and emissions. The rise of electrified engines, hybrid solutions, and alternative fuel concepts, such as hydrogen or e-fuels, further underscores the need for advancements in drivetrain components. These components play a vital role in transmitting the power generated by an engine to the road surface. While current designs achieve conversion rates of up to 97–99.5 percent of mechanical input power to usable output power, there is still significant potential for further improving the efficiency of gearboxes (Ref. 1). Enhancing gearbox efficiency not only reduces heat dissipation for a given power output but also enables the design of more compact cooling components. Optimizing lubrication flow in gearboxes can also minimize the amount of oil required to reduce friction between gears and dissipate heat from drivetrain components. With the advent of water-based lubricants, the innovation process also takes place on the material side. However, it is crucial to address emerging losses that become more pronounced at higher rotational speeds and lower loads, which are typical conditions for automotive transmissions operating at their top gear ratio (Ref. 2).

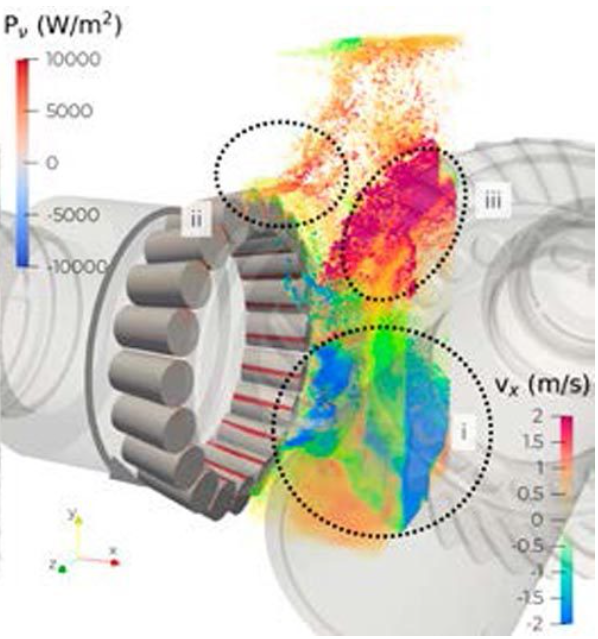

By gaining a comprehensive understanding of and effectively controlling the lubrication flow within transmissions, significant advancements can be made toward achieving more efficient and environmentally friendly gearboxes. This paper aims to investigate the mechanisms and origins of hydraulic losses in bevel-geared gearboxes, with the ultimate goal of identifying opportunities for constructive measures to optimize losses and increase overall efficiency. Through the utilization of the Smoothed Particle Hydrodynamics (SPH) method, this study provides a reliable and efficient tool for accurately analyzing fluid patterns and deriving hydraulic power losses within an acceptable industrial time frame of two days. The findings not only contribute to the understanding of loss sources and their physical origins but also highlight the potential of the SPH method for lubrication simulations and power loss optimization. Ultimately, the insights gained from this research will pave the way for reduced product development cycles and foster the use of efficient lubrication strategies in gearboxes.

Power losses within a gearbox are classified according to their component or origin, that is gears PLG, bearings PLB, seals, PLS, and other parts or auxiliary components, PLX, like clutches and electric pumps. Losses of the individual components are further divided into load-dependent, index L, and load-independent losses, sometimes referred to as spin or no-load losses, index 0. Following the notation of Niemann and Winter (Ref. 3), the power losses may be written as:

(1)

Load-dependent losses are typically determined by standards or in-house or commercial gearing pre-design tools. On the contrary, accurate prediction of load-independent losses requires an accurate prediction of the interaction between lubricant and fluid which is a priori unknown as all components interact with the lubricant in a coupled manner. The load-independent losses are grouped by their physical origin. Churning, index C, arises due to the parts moving the inertia of the oil by pressure and viscous forces acting from the fluid towards the wheel. Squeezing, index S, covers losses that are generated by the rapid volume changes in the periodically opening and closing meshing zone. Windage, index W, covers losses due to air resistance. This yields the general formulation of load-independent losses in a passive lubricated gearbox:

(2)

It has been commonly observed that losses due to air resistance are negligible for circumferential speeds below approximately 20 m/s (Refs. 4, 5). This paper only covers losses due to the fluid’s resistance to the gears and the bearing, ignoring the air’s presence. This loss share covers the previously described churning and squeezing effects and will be addressed as hydraulic losses in this paper.

Although experimental research on the topic of gear power losses has been conducted since mid of the 20th century (Ref. 6) and extensive studies have been made in the following decades (Refs. 7, 8), no general concept has been developed to accurately determine power losses for all components in a transmission. The difficulty stems from the fact that the fluid flow within gearboxes is inherently complex. This is caused by the complexly shaped bodies churning through the lubricant-air mixture. The fluid phenomena for bevel gears are inherently more dynamic than cylindrical gears due to their exposed three-dimensional shape and mounting position. Only a little research on bevel gear churning losses has been conducted. Experimental studies on single rotating bevel gears made by Laruelle et al. (Ref. 4) propose a formulation for the churning torque over filling height, gear radius, and rotational speed for different fluid regimes. Quiban et al. (Ref. 9) updated these formulations and highlighted the phenomena of decreasing churning torques for dynamically varying filling heights. A broad range of tests for different hypoid gears, rotational speed, oils, attitudes, and single and meshing gears have been conducted by Jeon (Ref. 10). This study provides quantitative measurements for a specific gearbox. Therefore, his findings cannot be applied to arbitrary bevel-geared transmissions.

With the advent of high-performance computing and the progress of computational fluid dynamic (CFD) methods, simulations of the motion of the fluid within a gearbox became feasible (Refs. 11, 12). Subsequently, it was demonstrated that CFD is capable of accurately reproducing the fluid dynamics observed in experiments (Ref. 13). The investigations of the last decades are based on traditional CFD approaches that utilize a grid-based Eulerian technique. These methods are established but have to cope with major difficulties: With increasing complexity, that is more moving geometries, narrow gaps, and large geometry curvature, generating a sophisticated computational grid becomes difficult (Refs. 14, 15). Tracking the complex phase interface between air and oil requires a sufficiently fine mesh and the transient deformation of the domain with its moving parts requires adapting the grid over time. These demands raise the computational effort drastically. A variety of mesh and geometry handling techniques are employed to cope with this matter. A summary is given in Concli and Gorla (Ref. 16) and Concli et al. (Ref. 15). However, these methods have been proven to reliably predict churning losses in gears (Refs. 12, 13, 15). A sophisticated overview of state-of-the-art CFD research in numerical drivetrain lubrication applications is given in Maccioni and Concli (Ref. 17). It is carved out that individual methods exist to address hydraulic losses in bearings, gearsets, or pumps individually with more than 80 percent agreement between simulation and experiment. However, most of those papers focus solely on one of those mechanical components per simulation. Considering grid-based methods, e.g., Peng et al. (Ref. 18) presented qualitative results of an automotive rear axle gearbox with rotating bearings and validated their method with experimental values in a specialized test rig considering gears only. Oil, operating conditions, and filling heights are comparable to this paper. The simulation domain was separated into individual mesh zones, where motions were applied by user-defined functions. No detailed assessment of the bearing-induced churning losses is presented.

Smoothed Particle Hydrodynamics (SPH) is a Lagrangian CFD technique that has lower demands on geometry quality, thus decreasing simulation preparation time drastically. Mathematically, this approach renders a moving and deforming grid method where the collocation points are commonly called particles. Since neighboring relationships are updated after advecting the particles no computational grid is required. Here, particles of distinct fluid types represent individual phases and the unique particle type implicitly reconstructs the phase interface. Apart from the native handling of free surface flows, SPH has also proven to provide computational advantages for drivetrain simulations. Keller et al. (Ref. 19), as well as Maier et al. (Ref. 20), conducted SPH simulations 20–25 times faster than a Eulerian simulation of the same problem. These aspects indicate the significant potential of the SPH method in the field of transmission CFD. Being mesh-free, it simplifies the time-consuming geometry preparation and the simulation itself, by making typical procedures such as remeshing or gear-scaling obsolete. Although overall fluid flow was reproduced accurately (Refs. 21–24) this method has not yet been proven to replicate the measured churning losses for various cases with an accuracy of over 80 percent (Refs. 17, 22). The main reason lies in under-resolving pressure gradients in the contacting areas and velocity gradients in churning regions. Multiple approaches with artificially increased fluid-wall friction are employed to calibrate results closer to the experimentally expected values. Contrary to the previous papers, the utilized SPH solver comes with the following differences:

It imposes the boundary-particle interaction by considering the shape of the boundary, i.e., evaluating the boundary integral of the particle’s kernel with the solid wall to ensure consistency of the kernel integration scheme. This is not ensured by employing dummy boundary particles or polygonal wall-distance-force functions (Refs. 25, 26) are used to describe the interaction of the fluid with the wall, which will inevitably lead to substantial spatial resolution dependencies.

Using multiple particle resolutions per simulation to improve resolving the pressure gradients and fluid boundary layers.

No usage of artificially increased forces between fluid-wall and fluid-fluid interaction to calibrate results to experimental data.

Moving particle semi-implicit (MPS) characterizes another Lagrangian CFD method. Both MPS and SPH are very similar in their numerical approach as shown in Soute-Iglesias et al. (Ref. 27). Again, multiple studies report accurate prediction of visual oil distribution within gearboxes (Ref. 25, 28). The churning loss determined by applying the MPS method on a high-speed railway system is qualitatively investigated in a similar study conducted by Deng et al. (Ref. 29) as well as in Shao et al. (Ref. 26). A similar qualitative study is presented in Singh et al. (Ref. 24). The results presented are derived from an implicit MPS solver that allows for theoretically larger time steps than the explicit SPH solver in this paper. However, implicit solvers have the disadvantage of solving the pressure Poisson equation by a computationally costly matrix inversion. Additionally, presented hydraulic losses for bearings were reported to be negligible low, i.e. one to two orders of magnitude smaller than the gear-induced hydraulic losses.

This paper outlines a methodology for investigating churning losses of gears and bearings simultaneously in an industrial gearbox by bridging the fluid scale differences with particle-refinement techniques in SPH and subsystem investigations of the bearings. A special focus is set on the importance of replicating the roller bearing’s motion correctly instead of a simple rigid rotation. The method is applied as a parameter study considering rotational speed, turning direction, and filling height to highlight the benefits of cloud-native high-performance computing for virtually replicating experimental test rigs to derive a reliable system response within a few days without building a prototype.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Timken to Participate in the Evercore ISI Industrial Conference

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.