SPRUTCAM X AND SPRUTCAM X ROBOT 17.0.13 UPDATE

SprutCAM Tech is thrilled to announce the rollout of the SprutCAM X and SprutCAM X Robot 17.0.13 update, a significant enhancement packed with more than 100 changes, including workflow improvements and bug fixes.

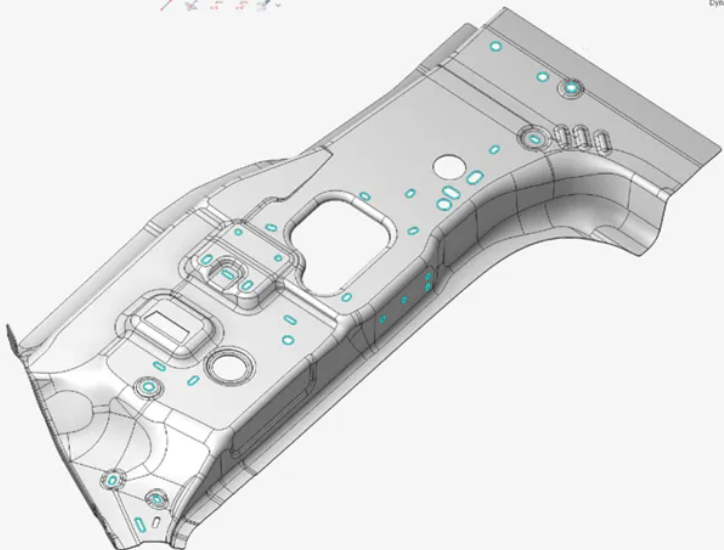

Enhanced Job Assignment for 6D Contour operations:

A new feature enables the detection and selection of part pocket edges with a simple double-click while holding the SHIFT key, streamlining the selection process for all identical pockets for machining.

Spline handling improvements:

In the Machining window on the Job Assignment tab, users will find updated functionalities for working with splines, including:

• SHIFT key selection now allows for a sequence of points to be selected, with selected points highlighted in blue for better visibility.

• Shift and Rotate operations for points and entire splines are significantly faster.

• Transformation parameters are now displayed only for a single selected point, improving clarity and focus.

• Undo/Redo options have been added for the Shift, Rotate, and Delete operations on spline points.

• Added confirmation message when deleting a spline

• Drawing splines with a high point count is now much faster, reducing wait times.

Machining Reports updates:

• Issues with the handling of images in reports have been fixed and a simplified report output mode has been introduced.

• Custom variables can now be included in reports for more personalized documentation.

• Detailed guidance is accessible through the tutorial found under the question mark icon in SprutCAM X, with the new chapter 3.7 providing in-depth information.

Usability and convenience enhancements:

• MachineMaker updates for Fanuc and Dobot robots: Support for multiple tool center points (TCPs) has been added, expanding compatibility.

• User interface enhancements: Updated interactive Smart Hints, improved tool orientation algorithm for robots with positioners, and added drag-and-drop functionality for the thread library window in lathe operations.

• The visibility buttons now automatically adapt to the operation mode, enhancing user interface intuitiveness.

• Updated MachineMaker documentation.

• Increased size of value entry fields in the Machine control panel.

• For Welding and 6D contouring operations, the ability to interactively set Approach and Retract has been added

• When working in the 3D CAD module, the ability to snap to objects in planes other than the active plane has been added.

The Our latest software update includes a number of fixes to improve functionality and usability. Major fixes include correcting simulation errors in multi-task machining, refining the post processor tutorial, and resolving issues with 5D Surfacing and Waterline undercut operations. We've also addressed machining project challenges, such as errors when saving projects and exporting from MachineMaker to SprutCAM X, and improved system stability and performance, particularly in RAM management and tool visualization.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.