SANDVIK COROMANT'S SUSTAINABILITY ANALYZER TOOL

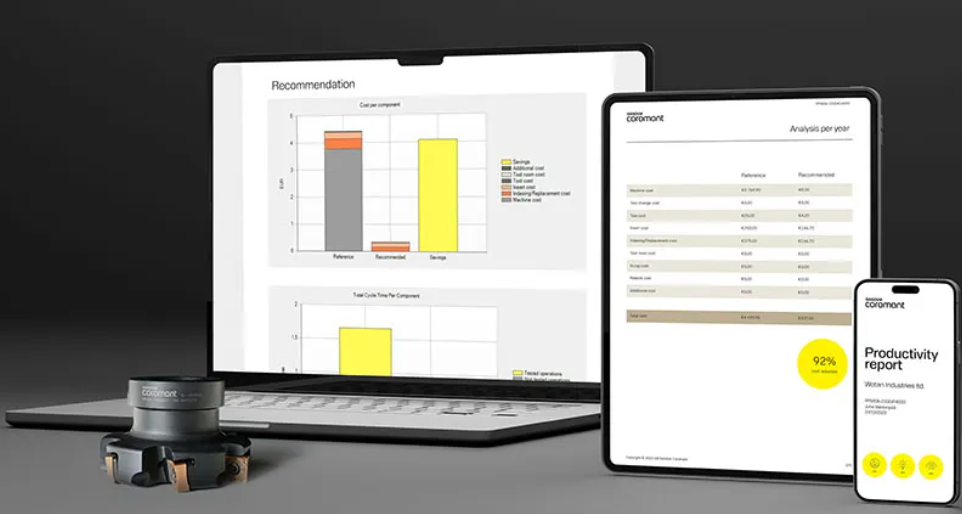

Sandvik Coromant, a global leader in metal cutting tools and manufacturing solutions, has recently launched its new Sustainability Analyzer, an upgraded version of the company’s existing Productivity Analyzer tool. The new Sustainability Analyzer enables machining customers to capture, measure and analyze data on their energy consumption and CO2 emissions to support their transition toward more sustainable manufacturing practices.

“As the manufacturing industry works to reduce its carbon footprint, having accurate data on energy usage and emissions is essential to driving meaningful improvements,” says Patrik Eurenius, head of sustainability and EHS at Sandvik Coromant. “Our new Sustainability Analyzer empowers our customers with the insights they need to make informed decisions and take tangible steps toward decreasing their environmental impact.”

The Sustainability Analyzer builds upon Sandvik Coromant’s existing Productivity Analyzer, which has already helped customers save nearly 2 million production hours. The new tool provides detailed reporting on energy consumption per component, annual energy usage and annual CO2 emissions. It leverages data from Sandvik Coromant’s CoroPlus Tool Guide to calculate these sustainability metrics based on factors such as machine efficiency, local energy prices and material properties.

In a recent test case with a leading automotive manufacturer, the Sustainability Analyzer helped the customer identify a 15% increase in productivity and a 23% reduction in energy consumption per component. Armed with these insights, the customer is now better equipped to make strategic decisions to further reduce their environmental impact.

“Sandvik Coromant is committed to helping our customers achieve their sustainability goals,” adds Eurenius. “By providing data-driven tools like the Sustainability Analyzer, we’re empowering manufacturers to measure their progress and take meaningful action toward future-proofing their business.”

The new Sustainability Analyzer is available to all Sandvik Coromant customers as part of the company’s broader Manufacturing Wellness initiative, which promotes sustainable manufacturing practices.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Understanding Cycloidal Gearboxes - Single-stage vs Multi-stage

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.