Regal Rexnord Features Rugged and Reliable Solutions at AISTech

Regal Rexnord Corporation recently displayed its solutions for the metals industry at AISTech 2024.

Regal Rexnord's extensive portfolio of powertrain products is backed by global design engineering, field service and rebuild/repair teams. Solutions are designed to withstand harsh mill environments while also providing exceptional personnel safety and equipment protection. Regal Rexnord delivers a comprehensive offering of mill spindles, couplings, U-joints, gear motors, speed reducers, torque-limiting devices and backstop clutches to meet the specific needs of the metals industry.

Products featured at AISTech 2024 included:

Powertrain solutions:

For operations with cranes, Regal Rexnord showcased powertrain assemblies (including gearbox, couplings and brakes) for all crane types, including port, gantry, charging/ladle, tundish, scrapyard, coil and billet.

Bearings:

Where static and dynamic misalignment is present, Rollway Unmounted Spherical Bearings are the ideal solution, helping operations address challenges in even the harshest conditions.

Operations can meet their needs with a wide range of customizable options thanks to durable, high-performing Rex and Link-Belt Mounted Spherical Roller Bearings.

Couplings:

Optimized for the most demanding applications, the torque-dense Kop-Flex Series H Plus Gear Coupling features high misalignment capability thanks to crowned hub teeth with flank, tip and root curvature. Large bore capacity accommodates large shaft diameters without increasing the coupling size, resulting in cost savings.

Jaure BARFLEX TCBR Barrel Couplings offer nearly 10 percent higher torque capacity than the TCB-HD coupling.

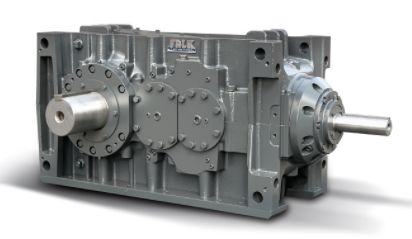

Gear Drives:

With its cooler operating temperature, optimal power and advanced technology, the Falk V-Class Gear Drive outperforms and outlasts the competition.

Rexnord Planetgear Gear Drives feature rugged designs are proven to meet operating challenges in the world’s most demanding applications. Concentric inline gear reducers offer reliable operation through self-aligning planet carriers that float radially and axially to provide perfect alignment of the drivetrain.

Intelligent Reliability Services and IIoT:

Remote vibration, temperature and torque monitoring from Perceptiv condition monitoring systems empower local teams to use predictive maintenance to plan ahead and extend equipment life. Perceptiv Intelligent Reliability Solutions provide real-time insights to monitor equipment performance remotely so operations can prevent costly downtime.

Brakes

The Stromag Safety Drum Brake (SAB) features spring-applied, electrohydraulic-thrustor-released technology. Equipped with an automatic wear compensation to ensure constant torque, the SAB is a favorite among steel mill operators.

The Stearns AAB 361 Series Crane Brake is a maintenance-friendly, easy assembly option for portal crane applications. Brake gaskets are captive (O-ring), which prevents part loss during maintenance.

Gear Spindles

Amerigear Mill Spindles are designed for medium torque mill applications and auxiliary equipment where high misalignment capacity is required and where equipment must be disconnected quickly and frequently. Typical applications include drives for levelers, uncoilers, side trimmers, tension, runout tables, pinch rolls, brush rolls, bridles, flatteners and scale breakers.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.