What are the installation methods and precautions for turntable bearings?

What are the installation methods and precautions for turntable bearings?

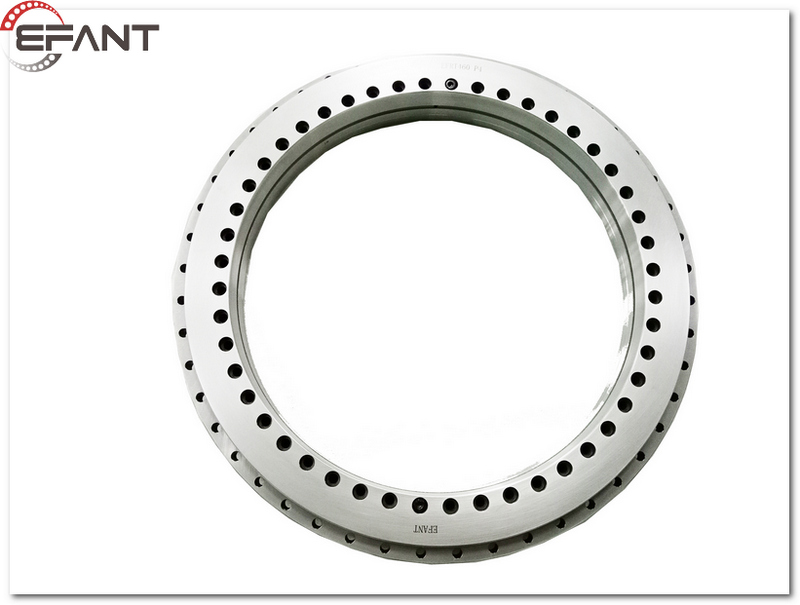

As a precision bearing, the turntable bearing has a compact structure and convenient installation characteristics, which can be widely used in various fields. According to different installation requirements, it can be divided into two installation methods.

Treatment before installation of turntable bearings:

1. Rust prevention treatment

The inner and outer surfaces of the turntable bearings need to be evenly coated with anti rust lubricating oil on both sides of the bearings. The anti rust period of the turntable bearings is generally 12 months after leaving the factory. If the storage time exceeds 12 months, a new anti rust treatment should be carried out.

2. Packaging

The packaging can be wrapped with plastic film or kraft paper, and the outer part of large rotary bearings should be wrapped and sealed with plastic cloth. For small rotary bearings, they should be packaged in wooden boxes.

3. Placement

When multiple turntable bearings are stacked together, shims should be evenly placed between each set of bearings, and the placement position of each layer of shims should be consistent.

Installation method of turntable bearings:

1. Cold installation

When installing small bearings with different models, the bearing can be installed in the appropriate position by gently tapping the sleeve and hammering it. During operation, it is important to apply as evenly as possible on the bearing ring to prevent the bearing from tilting.

2. Hot installation

Usually, for larger disc bearings, cold installation cannot be used for installation. It is necessary to first heat the bearings and bearing seats before proceeding with the relevant installation. When heating bearings, attention should be paid to evenly heating to avoid local overheating.

Precautions for installing turntable bearings:

1. Installation environment requirements

Choose to install in a dry and dust-free area, and keep away from equipment that may produce metal debris and dust. In unavoidable cases, the impact of pollution should be minimized.

2. Cold installation pressure

Cold installation often uses the pressing method for installation. If the inner and outer rings of the bearing are to be installed on the shaft and the bearing seat simultaneously, it must be ensured that the same pressure is applied to the inner and outer rings simultaneously, and the contact surface with the installation tool must be on the same plane.

3. Hot installation temperature

During the hot installation process, the bearing temperature should be controlled below 727 degrees Celsius to avoid changes in the internal metallographic structure of the bearing steel caused by overheating. When the bearing cools down, it cannot return to its original size.

Why do turntable bearings rust?

In the application of turntable bearings, rusting is a common problem, but few people understand the reasons for its rusting. So, what is the ultimate reason for bearing rusting?

1. Some manufacturers do not strictly follow the correct methods in the production process of bearings, resulting in poor quality of the bearings produced.

2. Some production enterprises may use unadorned materials for production in order to obtain greater profits, which may lead to a decrease in the quality of the turntable bearings.

3. The quality of anti rust lubricating oil and cleaning oil used in bearings does not meet the requirements of the process technology regulations.

4. The packaging materials for bearings such as anti rust paper, nylon paper (bags), and plastic drums do not meet the requirements for anti rust packaging of rotary table bearing oil seals, which is also one of the factors that cause rust.

5. Due to the harsh operating environment, the bearings were not cleaned up in a timely manner during use, resulting in inadequate maintenance and rusting.

Contact

Company:Luoyang EFANT Precision Bearing Manufacturing Co. Ltd

Address:No. 9 Jingjin North Rd, Luoxin Development Zone,

Xin'an County, Luoyang City, Henan Province 471003, China

Tel:86-379-80887690

export@efindbearing.com

https://www.efindbearing.com/contact-us

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.