What are slewing bearings?

What are slewing bearings?

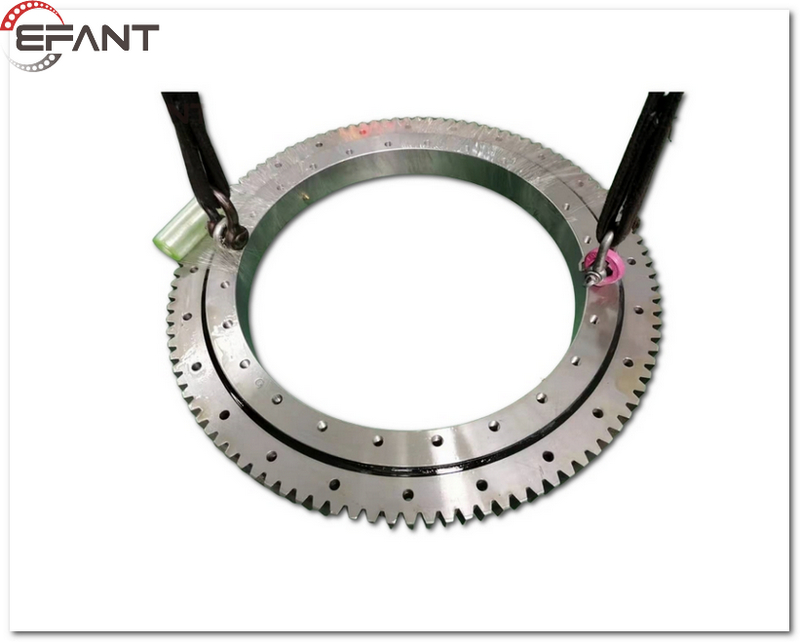

Slewing bearings are a type of large, oversized rolling bearings with a special structure that can simultaneously withstand combined loads such as axial load, radial load, and overturning torque. They have high load capacity and integrate multiple functions such as support, rotation, transmission, and fixation. The main characteristic of slewing bearings compared to general rolling bearings in terms of bearing capacity is that they can withstand large eccentric loads (i.e. overturning moments), and the bearing capacity is greatly related to the eccentricity of the load. The vast majority of slewing bearings have installation holes, lubrication holes, and sealing devices in their structure. Therefore, slewing bearings have the characteristics of compact structure, simple installation, and easy maintenance.

Classification of slewing bearings:

slewing bearings can be divided into different structural forms based on different types, such as four point contact ball slewing bearings, double row differential diameter ball slewing bearings, cross cylindrical roller slewing bearings, and three row cylindrical roller combination slewing bearings; The above types of bearings are divided into different structures based on whether they have teeth and the distribution of teeth, such as toothless, external tooth, and internal tooth.

The slewing bearing can meet the needs of the working host under various load conditions according to different structural characteristics. Among them, the four point contact ball slewinge bearing has a high dynamic load capacity, the cross cylindrical roller slewing bearing has a high static load capacity, and the three row cylindrical roller combination slewing bearing, due to the increase in load capacity directed towards the height direction of the bearing, is subjected to various loads by different raceways and roller groups. Therefore, under the same force conditions, the diameter of the bearing can be greatly reduced, making the main engine more compact. It is a type of slewing bearing with high load capacity.

The code representation for slewing bearings:

The bearing code consists of a basic code and a post code. The basic code is divided into three parts. The front part is the structural type and transmission type code, the middle part is the diameter of the rolling element (the maximum diameter for bearings with two or more rows of rolling elements), and the rear part is the diameter of the center circle of the rolling element (the maximum diameter for bearings with two or more rows of rolling elements).

Installation of slewing bearings:

Slewing bearing is a special structural large bearing that can simultaneously withstand large axial loads, radial loads, and overturning moments, and integrates multiple functions such as support, rotation, transmission, and fixation. Therefore, when installing the slewing bearings, it is necessary to do a good job of relevant inspections or precautions during installation. For such large bearings, we must do a good job of maintenance, storage, and other work to prevent the slewing bearings from being damaged and unable to be used normally.

Before installing the slewing bearing, it is necessary to inspect the installation surface of the main machine. The supporting parts should have sufficient strength, the connecting surface should be machined, and the surface should be flat without debris and burrs. For those that cannot achieve the required flatness through mechanical processing, special plastic with high injection strength can be used as fillers to ensure the accuracy of the installation plane and reduce vibration. The ring of the slewing bearing has a quenched soft band area, which is marked with "S" on the end face of the ring. When installing, the position of the soft band should be placed in the non load area or non frequent load area (the plug hole is always located at the soft band).

When installing the slewing bearing, radial positioning should be carried out first, and the installation bolts should be tightened in a cross manner, and the rotation of the bearing should be checked. When tightening bolts, there should be sufficient pre tightening force, which should be 70% of the yield limit of the bolt material. Installation bolts should be equipped with quenched and tempered flat washers, and the use of spring washers is strictly prohibited.

Maintenance of slewing bearings:

After the installed and put into operation slewing bearings have been continuously running for 100 hours, a comprehensive inspection should be conducted to ensure that the pre tightening torque of the installation bolts meets the requirements. The above inspection should be repeated every 500 hours of continuous operation thereafter. After the installation of the slewing bearing, an appropriate amount of lubricating grease should be filled, and the bearing should be rotated while filling to ensure even distribution of lubricating grease. After working for a period of time, the slewing bearing inevitably loses some lubricating grease. Therefore, lubricating grease should be replenished every 50-100 hours for the normal operation of the slewinge bearing.

Transportation and storage of slewing bearings:

During transportation, bearings should be placed horizontally on transportation vehicles, and measures should be taken to prevent sliding and vibration. If necessary, auxiliary supports should be added.

Application of slewing bearings:

In general, the slewingv bearing itself has installation holes, lubricating oil holes, and sealing devices, which can meet the different needs of various types of hosts working under different working conditions; On the other hand, slewing bearings themselves have the characteristics of compact structure, convenient guidance for rotation, easy installation and maintenance, and are widely used in large and medium-sized rotary equipment such as lifting and transportation machinery, metallurgical machinery, mining machinery, construction machinery, port machinery, and automated assembly lines.

Contact

Company:Luoyang EFANT Precision Bearing Manufacturing Co. Ltd

Address:No. 9 Jingjin North Rd, Luoxin Development Zone,

Xin'an County, Luoyang City, Henan Province 471003, China

Tel:86-379-80887690

export@efindbearing.com

https://www.efindbearing.com/contact-us

https://www.efindbearing.com/slewing-bearing/012-30-710-external-gear-slewing-bearing.html

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next What are the installation methods and precautions for turntable bearings?

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.