China Tianma Bearing takes the lead in developing high-end bearing condition monitoring and health management technology by big data

On June 6, 2024, the Industrial Development Promotion Center of the Ministry of Industry and Information Technology organized a key project "Facing Big Data" under the national key research and development plan "Manufacturing Basic Technology and Key Components" in Huzhou, Zhejiang, led by Zhejiang Tianma Bearing Group Co., Ltd. Comprehensive performance evaluation meeting of the "High-end Bearing Condition Monitoring and Health Management Technology" project. The expert group believes that the project has completed the tasks and assessment indicators specified in the mission statement and achieved the expected goals.

In order to quickly improve the intelligent operation and maintenance level of China's major equipment, in November 2020, the "High-end Bearing Condition Monitoring and Health Management Technology for Big Data" project led by Zhejiang Tianma Bearing Group Co., Ltd. was listed as a national key research and development plan. "Basic Manufacturing Technology and Key Components" key project. The project leader is Professor Cao Hongrui of Xi'an Jiaotong University. Other participating units include Shijiazhuang Railway University, Huazhong University of Science and Technology, Shanghai Jiao Tong University, Xi'an Jiaotong University, Tsinghua University, Shanghai University of Technology, as well as CRRC Tangshan Locomotive and Rolling Stock Co., Ltd., Shandong CRRC Wind Power Co., Ltd., Zhejiang Heqing Flexible Electronic Technology Co., Ltd.

Over the past three years, the research team has conducted research on the scientific issue of intelligent analysis and diagnosis prediction mechanism of bearing fault information under big data to address the low accuracy of bearing fault diagnosis and difficulty in predicting maintenance of major equipment such as wind power and high-speed trains, and has made breakthroughs in bearing monitoring. High-quality and complete acquisition of heterogeneous big data from multiple sources, construction of health monitoring indicators and dynamic monitoring of changing working conditions, intelligent diagnosis of deep migration of multiple faults in bearings under big data, bearing performance evaluation and life prediction driven by digital twins, remote monitoring and health management Five key technologies, including system cloud-edge collaborative development, completed the project mission objectives and all assessment indicators. The project integrated theoretical methods with key technologies, developed a high-end bearing condition monitoring and health management system, and conducted application verification in 5 companies in the wind power and rail transit industries, promoting the shift from "regular maintenance" to wind power, rail transit and other industries. “Predictive maintenance”. The important achievements, innovation, application prospects and demonstration promotion of the project are as follows:

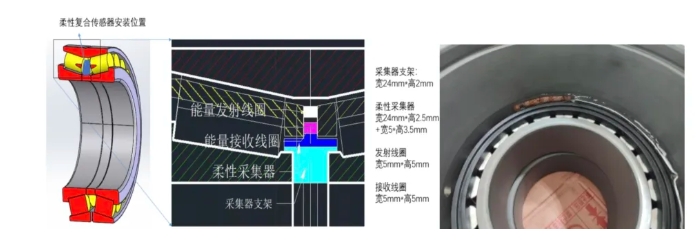

1. Breakthrough in the preparation technology of flexible composite sensors, and developed bearing prototypes integrating flexible composite sensors, which realizes embedded sensing of vibration, temperature, strain and other signals, solving the problem of small installation space of wind power and high-speed train bearings and difficulty in close proximity of sensors Installation and other issues.

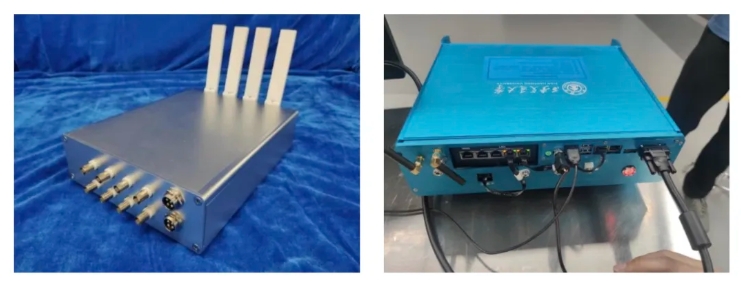

2. Proposed the construction and adaptive adjustment method of variable working condition bearing condition monitoring indicators, developed a multi-source signal collection and monitoring indicator edge computing engineering prototype, and realized the high-speed collection of bearing multi-source signals and the rapid calculation of status indicators. It has the functions of calculating time-domain statistics, frequency-domain statistics, time-frequency domain indicators, time-domain synchronous average indicators, residual signal indicators, differential signal indicators, etc. It has high technical maturity and meets engineering needs. It has been used in Baoji CRRC Times Engineering Machinery Co., Ltd. Companies and other enterprises apply.

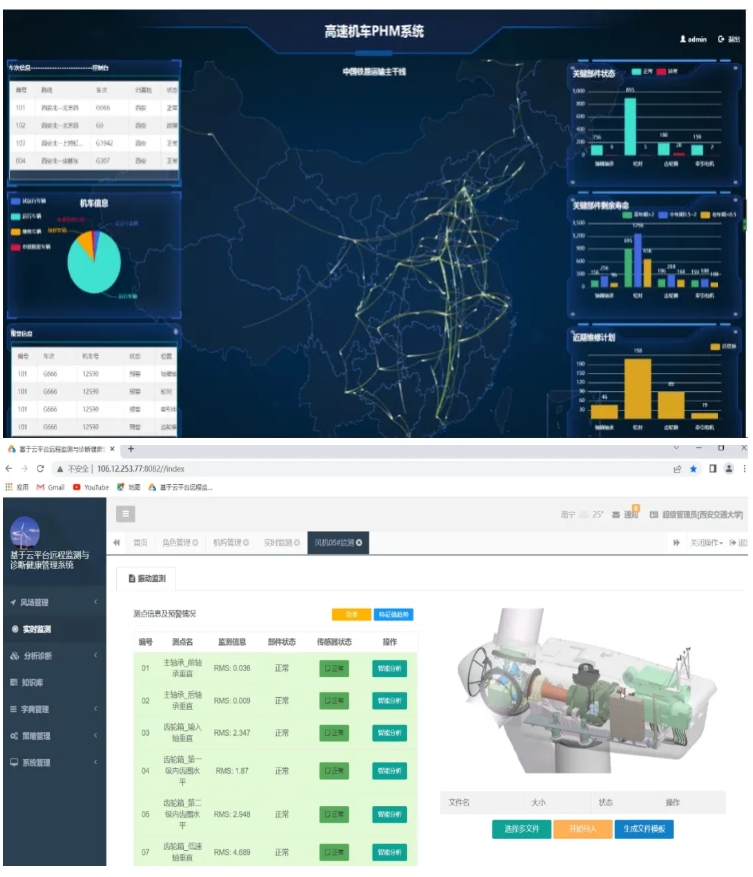

3. Proposed intelligent diagnosis and remaining life prediction methods for deep migration of multiple faults in bearings, developed a high-end bearing status remote monitoring and health management system based on a big data cloud platform, and realized intelligent diagnosis of typical bearing faults and prediction of remaining life under complex service conditions. . The research results have been applied and verified in relevant enterprises in the wind power and rail transit industries.

After actual testing, the technical achievements of this project can achieve a false alarm rate and false alarm rate of no more than 10% in early bearing failure monitoring under complex and changeable working conditions, a typical fault diagnosis rate of more than 95%, and a relative error of less than 15% in the prediction of the remaining life of the bearing. %, many indicators have reached the international advanced level in similar technical fields, helping to rapidly improve the intelligent operation and maintenance level of China's major equipment.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.