Festo Introduces ELGD-Based Handling System

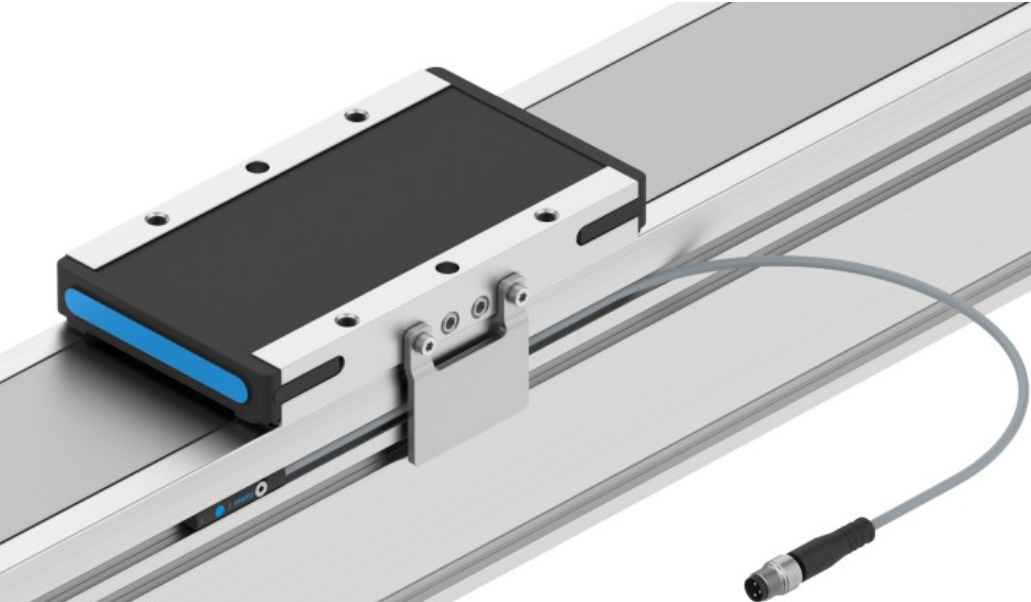

Festo introduced its newest generation of Cartesian-handling-system mechanical axes at Automate 2024. The ELGD-TB, tooth belt, and ELGD-BS, ball screw, axes feature an innovative Festo design for high-load bearing and compact size. These axes are manufactured on two new global-scale manufacturing lines to ensure competitive price, performance, and availability.

Festo demonstrated an integrated dispensing, gluing, and picking-and-placing electric light assembly cell. The cell simulates an actual application and features ELGD-based handling systems. The demonstration showcases the application’s precision and versatility in performing three assembly functions, all in a compact footprint.

Suited to most electromechanical handling tasks, the ELGD series brings specific benefits to applications, such as:

Cantilever systems and pick-and-place solutions for small parts handling, where short cycle times, high precision, and repeatability are key handling systems for top loaders, which benefit from the ELGD’s attractive price/performance ratio, high travel speed, and long stroke lengths.

Automation of 3D printing, additive manufacturing, dosing, gluing, and picking and placing are enhanced with the ELGD’s dynamic, virtually vibration-free movement.

Festo inlaid the bearings into the aluminum extrusion and extended bearings to the full width of the axis. This design enhancement enables high loads in a compact footprint. Machine builders can pack even more powerful tooth belt or ball screw axes in smaller footprint systems to achieve excellent feed forces and acceleration profiles. The integrated bearing design also enabled Festo to develop the lower profile ELGD-WD (wide actuator) for reduced force applications. This low-profile ELGD is 30 percent lighter than larger units while its rigidity and guide load capacity are similar.

The ELGD features a stainless-steel cover strip, which minimizes particle emissions in cleanroom applications and reduces ingress of particles in dirty environments. Festo enhanced particle emissions capability by including a pneumatic connection to provide sealing air (0.1 – 0.2 Bar) or a vacuum to the internal structure of the mechanics. Another innovation is the magnetic deflection of the cover strip, which eliminates mechanical wear and further reduces the likelihood of particle emissions.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Faulhaber Introduces New Motion Control System

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.