Use of Gear Reliability Data in a Cloud-Based Gearbox Digital Twin Using Telematics Data

In recent years, few terms in engineering have been given as much airtime as digital twin, however, it is often applied in so many different contexts that its interpretation has become extremely confused. The concept of a digital twin was described in 2001 in a presentation by Michael Grieves, being described as a “conceptual idea for PLM [Product Lifecycle Management]” (Ref. 1). In this, digital information would be a “twin” of the physical system, would be embedded within the physical system itself and be linked with that physical system through its entire lifecycle. Grieves expanded on the idea over subsequent years and by studying work by the same, originating author, it can be seen how the different interpretations of the term digital twin have arisen.

In 2016 (Ref. 1), Grieves expanded on the definitions, confirming that the digital twin covers all aspects of the product lifecycle, but with different purposes. For example, the digital twin prototype (DTP) covers the design phase, when the physical product does not actually exist. Following from this, the digital twin instance (DTI) is created as a digital representation of a specific physical product, to be linked to that physical product through its entire life. Interestingly, he goes on to talk about digital twin aggregates (DTAs), where data from multiple DTIs is aggregated within what he calls a digital twin environment (DTE).

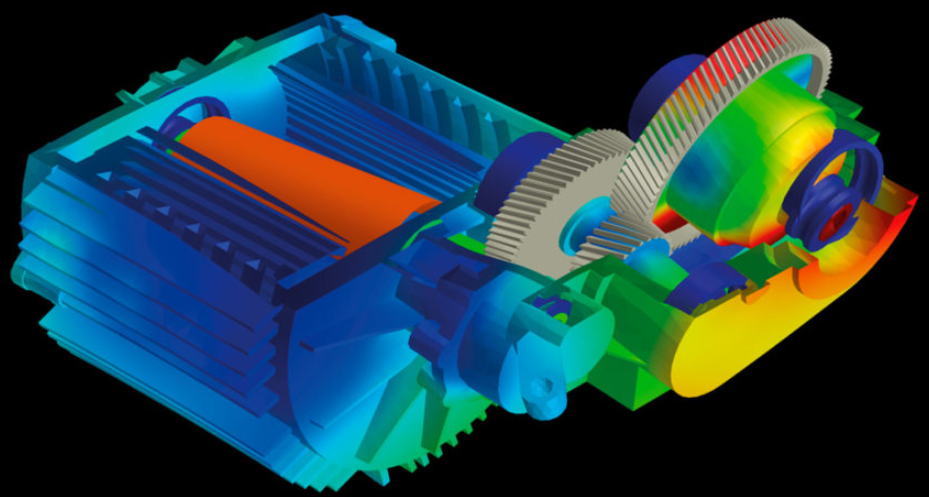

It is interesting to note that, using this definition, the digital twin prototype (DTP) aligns pretty well with another commonly used term, the design twin. Within this context, the DTP/design twin is clearly a computer simulation of the engineered system for use during the design phase. The author finds this curious since this is essentially a computer-aided engineering (CAE) model, provided to and used by industry for well over 30 years and promoted within the context of concurrent engineering, a theme that rose to prominence in the late 1980s. Whilst CAE models of many different systems exist, and may contribute to various Digital Twins, this is not the focus of this paper.

For this paper, the digital twin refers to a digital asset that exists alongside the physical asset during its operational life, providing insight into and feedback on the physical asset’s performance and health. Thus, the focus is on the DTI, with the potential to aggregate data into a DTA for the gearbox design being considered, and within the DTE set up by Hexagon.

In respect of the physical asset across its life, nothing is more important about its performance than its ability to function, i.e., reliability, and for CAE, nothing is of greater importance than to be able to predict the reliability of a product being designed. Thus, for this study, whilst gearbox noise, efficiency, and thermal behavior may be of interest, the primary interest is fatigue and reliability.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next IMCO'S M934 AND M935 CUTTING TOOLS

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.