The fundamental pillars of system engineering

As product design processes continue to evolve at unprecedented speed, engineers must not forget the fundamental pillars of systems engineering.

Alongside the rapid pace of technology development and increasing complexity of the design process, getting a product to market quickly is paramount. Whilst engineering design tools have evolved quickly in line with technology, however, the basic principles of robust engineering have not changed.

Saying this, dependencies on tool sets and the emergence of new project delivery frameworks have in someways distracted focus from the fundamentals, driving a need for a conscious grounding at an organisational level.

THREE PILLARS

The fundamental three pillars of systems engineering – people, tools, and processes – remain constant and all need to be developed together to realised engineering goals and outcomes. Dependency on one or neglect of another can create an inefficient system. The real world is far from perfect, however, and a pragmatic approach towards this ideal end goal is more realistic. A conscious understanding of this compromise enables engineers to take action to improve and evolve, so long as a growth and creative mindset is embraced.

MBSE TOOLSETS

One example of a tool that can upset this balance is the implementation of Model-Based Systems Engineering (MBSE) toolsets, which deliver advanced capabilities in terms of manipulation and visualisation of information that - as the volume of data continues to grow - prove invaluable. They are a blank canvas, though, and need a structure or framework to be applied to enable successful integration into an organisation.

As such, there are fundamental outputs that an organisation requires from an implementation of an MBSE system for the rest of the product development efforts to be successful: The people and process pillars need to be integrated properly.

Systems engineering is certainly not new, yet it still has an air of speciality about it. As an engineering consultancy, Hallmark Engineering Group believes that systems engineering principles are aligned with general robust engineering principles and the two should not be viewed differently. Systems engineering processes and techniques support product development of both simple and complex systems, and if viewed as a set of tools that can be consciously selected as appropriate for the project in hand, the scale of activity can be set accordingly. To this end, these fundamental skills and toolsets should be accessible to all.

REWORK CAUSES CHALLENGES

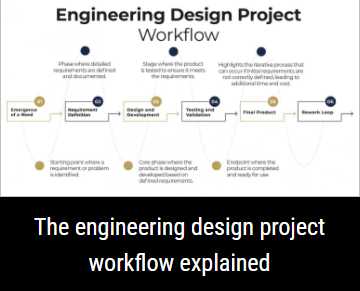

Simplistically, the key aim of an engineering design project is to get from ‘A’ to ‘B’ as quickly and efficiently as possible, with ‘A’ being the emergence of a need, and ‘B’ being a functional product used effectively to fulfil this need. Rework is the biggest challenge as iterations cost time

and money.

With almost two decades of experience in product development, Hallmark Engineering Group has seen first-hand the true cost of rework, with incorrect or incomplete product definition being the biggest contributor. If engineers do not understand completely what problem the product is trying to solve, this will inevitably result in a product that does not completely resolve the problem. This involves all stakeholders throughout the lifecycle of the product to understand its requirements and how they interact with others, understand how a product can and should fail, and documenting this accurately in a way that can be verified. It is far more efficient to make the effort to do this robustly than to have a complete redesign later down the line.

One challenge with this approach is the tendency to over-polish the requirement set and not progress to the design and development phase. It is important to maintain project governance and an understanding of risk to enable a pragmatic approach and maintain the desired outcome. Balancing all three pillars is the key to success, and a pragmatic approach in applications with a growth mindset is the only way to achieve it.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.