MASTERCAM 2025 SOFTWARE

Mastercam, the industry leader in CAD/CAM solutions, proudly announces the release of Mastercam 2025. This latest version introduces cutting-edge features and enhancements designed to maximize speed, efficiency, and precision in your machining operations, setting a new benchmark in the industry.

During the Public Beta, manufacturers worldwide provided valuable feedback that shaped the final product, ensuring that Mastercam 2025 meets the essential demands of users while advancing productivity and sustainability in manufacturing.

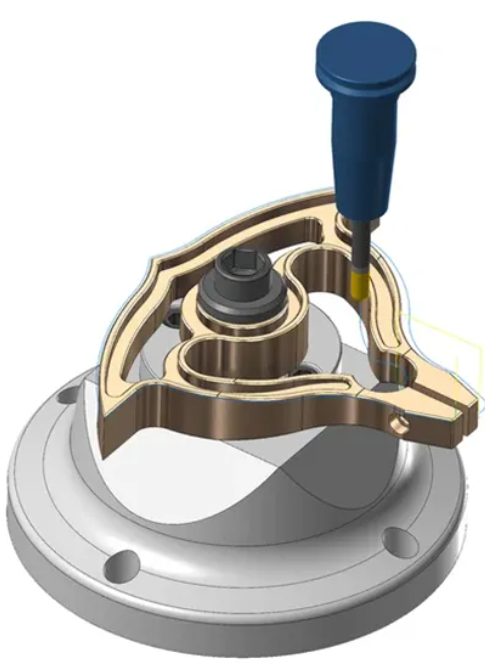

New Mastercam Deburr Solution

Introducing Mastercam Deburr for 3-axis, an advanced solution that revolutionizes the deburring process for Mastercam Mill, Mastercam Mill 3D, Mastercam Router, and Mastercam Mill-Turn. Designed to integrate seamlessly with your Mastercam products, this add-on simplifies deburring through automatic edge detection and intuitive controls. Mastercam Deburr allows users to leverage the streamlined deburr cycle in a 3-axis environment without requiring Mastercam Multiaxis, providing faster and more accurate deburring with less manual effort. For users with Mastercam Multiaxis, the familiar simplified controls ensure an easy transition.

Mastercam Deburr transforms the deburring process, saving time and enhancing deburr quality. This solution improves the efficiency and precision of deburring operations, reducing the need for manual intervention and ensuring consistent, high-quality results.

Productivity Enhancements

Mastercam 2025 also introduces finish passes to 2D Dynamic Mill and Area Mill toolpaths. The new Finish Passes page allows users to add high-speed finishing passes along the selected toolpath boundaries, with configurable parameters for feed rate and spindle speed overrides, ensuring a smooth and precise finish.

Advanced Capabilities

Mill-turn support for Y-axis turning is a significant addition in Mastercam 2025, enabling users to create toolpath planes with the correct tool orientation and spindle origin while taking advantage of the latest advances in Y-axis tool technology. The new A-axis contour turning toolpath complements the B-axis contour toolpath, extending support for rotary contour turning and allowing users to machine difficult-to-reach areas with ease.

Performance Boosts

Thread Mill operations in Mastercam 2025 benefit from enhancements such as Speed/Feed Override for Lead In/Out, which provides better control during entry/exit moves, promoting better tool life and more accurate machining of threads. The gradual Lead In/Out feature enhances tool control during engagement and disengagement for Thread Mill operations, while the new Tool Edge Feed Rate calculates feed rates based on the tool’s tangential edge for more precise machining.

Security Improvements

Mastercam 2025 introduces automatic license update notifications for software-based licenses. This feature saves time for users while keeping Mastercam secure with the latest license information and features.

These are just a few of the exciting new features and enhancements in Mastercam 2025. Discover how Mastercam 2025 can transform your machining operations and drive your business forward. For more information, visit Mastercam 2025.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.