New Integration of the Calculation of Gears, Shafts, and More in 3D CAD

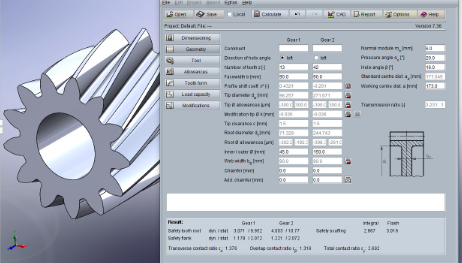

Calculation specialist GWJ Technology, a leading provider of calculation solutions for gears and other machine elements up to gearboxes, announces the availability of a new generation of its eAssistant integration modules for SOLIDWORKS, Autodesk Inventor and Solid Edge. The new generation of integration modules for the web-based calculation software eAssistant--the engineering assistant--is characterized in particular by a new way of calling up calculations directly from the CAD environment. The single calculation modules of the eAssistant can be started directly from the menu integrated in the respective CAD system. The previous method of starting the calculation modules via a browser such as Chrome, Edge or Firefox, which required downloading a start file and clicking on it, is now completely unnecessary. The modules are launched directly without any detours. This increases convenience and speeds up switching between design and calculation. Using these calculation integrations or CAD plugins, the corresponding 3D models can be automatically generated directly from the calculations performed for cylindrical gears, racks, involute splines, bevel gears or shafts using the native functions of the respective CAD system. The tooth form of involute gears is created based on a mathematical manufacturing simulation, similar to traditional manufacturing using hobbing or gear shaping for a specified tolerance position. This means that the 3D models can be used directly for manufacturing, such as 3D printing, wire eroding, laser cutting, etc. In addition, the calculation information is stored in the generated models. This allows the original calculation to be accessed directly from the 3D CAD model. The calculation can then be modified and the already created component can be adjusted. In addition, spur gears or splined shafts/hubs can be cut into existing models. It is also possible to automatically generate design tables with manufacturing data directly on the drawing. This eliminates errors in transmitting basic gear and test data, making work faster and easier. These tables can also be customized using templates. Multiple templates for the same gear type are possible. The appropriate template can then be selected directly from a list box before it is placed on the drawing.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next OES Releases Series of Lift and Pitch Stages

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.