Rating of Machine Elements with a Load Spectrum

The rating of machine elements of a drive system is defined by national or international standards. Generally, a standard provides the calculation methods for the rating with a nominal load. Rules for the consideration of load spectrums are often missing. In this chapter, the methods for the verification of the most critical elements—gears, shaft, and bearings—with a load spectrum are discussed. Rating of Gears with a Load Spectrum Part 6 of the ISO6336 standard is the rule for the “Calculation of service life under variable load” (Ref. 3). The method is based on the Palmgren-Miner rule, which is a widely used linear damage accumulation method. The method is “neutral,” which means specific factors of the rating method used are not involved. Therefore, this rule can also be used in combination with AGMA ratings (as AGMA 2001 (Ref. 4) and others). AGMA rating methods do not give a rule for nonuniform load, but reference is given to use Miner’s rule as presented in ISO/TR 10495 [Chapter 7.2 in Ref. 4]). ISO/TR 10495 was replaced in 2006 by ISO 6336-6. To also handle cases with bins having negative torque (tooth loaded in the compressive stress domain) the rule for the alternating bending factor YM has to be extended (Ref. 1); and for every bin an individual YM1 and YM2 must be used. Rating of Bearings with a Load Spectrum A rule for the rating of bearings with load spectrum is not available in an international standard. The calculation procedure is based on the damage accumulation theory developed by A. Palmgren in 1924 and completed by B.F. Langer (1937) and M. Miner (1945). The formulae are well documented in the literature (Niemann-Winter ) or in handbooks of bearing manufacturers (Ref. 10). The main formula for the calculation of the total bearing service life by combining the service life per bin is documented in Equation 2. Service life may include the effect of lubrication and/or the modified reference rating according to ISO 16281.

Rating of Shafts with a Load Spectrum

The rating of shafts is not widespread. Until today, no ISO standard is available. Some national standards exist, but they are limited. DIN 743 (Ref. 8) contains indications concerning equivalently damaging stresses. But the only official method, that can cover and complete this task, is the German FKM Guideline (Ref. 5).

It must be noted that the symbols used in the FKM guideline are based on former East German TGL standards and unfortunately quite different from symbols used otherwise in literature, DIN, or ISO standards. All symbols used are listed in the symbol table of this paper.

The FKM Guideline contains variants of the calculation procedure for steel or other materials, as well as welded and nonwelded machine parts, and is therefore quite complex. For shaft verifications, the fatigue strength assessment with nominal stresses must be carried out. In this paper, only the main steps of the calculation with nominal stresses for steel using the method “Miner elementary” with the “equivalent amplitude assessment” rule (Ref. 5) will be summarized.

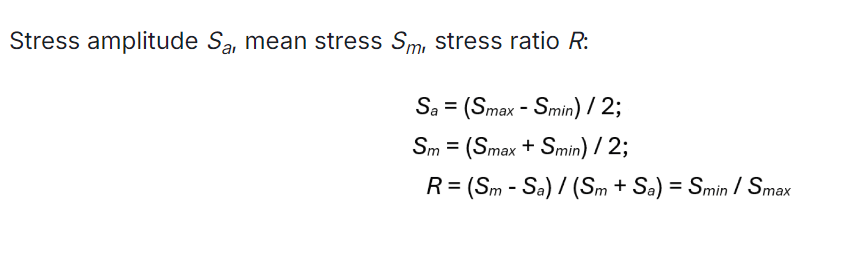

For shaft verification normally different shaft sections are selected, where a detailed analysis is made. In a section of a shaft, in general, there are different acting stress types: axial stress (tension or compression) Szd, bending stress Sb, torsional stress Tt, and shear stress Ts. Their maximum and minimum values (Smax, Smin or Tmax, Tmin) must be used. With a load spectrum, for every bin of the spectrum, in a determined section of the shaft the maximum loads must be calculated (axial force Fzd,max, bending moment Mb,max, torsional moment Mt,max, and shear force Q,max). Then the corresponding maximum stresses (axial Szd,max, bending Sb,max, torsion Tt,max, shear Ts,max) are found, using well-known equations (as in AGMA 6001, chapter 4.4, Ref. 13 or in Ref. 5, formula 1.1.1). The minimum stresses can be derived with the ratio factors:

The stress distribution in a shaft section is complex and different for the four acting stress types (Figure 5). At a specified point of a shaft section, the resulting stress is a combination of the four stress types, according to the normal stress hypothesis or the von-Mises criterion (Ref. 5). For nonwelded steel von-Mises is preferred. Usually, two points at the position W1 and W2 (Figure 5) of a shaft section are the highest loaded and should be checked. Verification with nominal stresses consists of a static strength assessment and a fatigue strength assessment. The static strength is checked with the bin of the load spectrum with the highest stresses. So for every bin the resulting combined stress (using the maximum stresses Szd,max, Sb,max, Tt,max, Ts,max) is calculated, and the verification is made with the highest value found. According to FKM the static assessment against the tensile stress Rm and against the yield strength Rp must be performed. Additionally in case of higher temperatures, the assessment against the creep strength Rm,Tt and against the creep limit Rp,Tt is required.

1.The news above mentioned with detailed source are from internet.We are trying our best to assure they are accurate ,timely and safe so as to let bearing users and sellers read more related info.However, it doesn't mean we agree with any point of view referred in above contents and we are not responsible for the authenticity. If you want to publish the news,please note the source and you will be legally responsible for the news published.

2.All news edited and translated by us are specially noted the source"CBCC".

3.For investors,please be cautious for all news.We don't bear any damage brought by late and inaccurate news.

4.If the news we published involves copyright of yours,just let us know.

Next Generation of a Load Spectrum for Shafts

BRIEF INTRODUCTION

Cnbearing is the No.1 bearing inquiry system and information service in China, dedicated to helping all bearing users and sellers throughout the world.

Cnbearing is supported by China National Bearing Industry Association, whose operation online is charged by China Bearing Unisun Tech. Co., Ltd.

China Bearing Unisun Tech. Co., Ltd owns all the rights. Since 2000, over 3,000 companies have been registered and enjoyed the company' s complete skillful service, which ranking many aspects in bearing industry at home and abroad with the most authority practical devices in China.